R7824, R7847, R7848, R7849, R7851, R7852, R7861, R7886 AMPLIFIERS FOR 7800 SERIES AND R7140 RELAY MODULES

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

65-0109—14 M.S. Rev. 06-11

Printed in U.S.A.

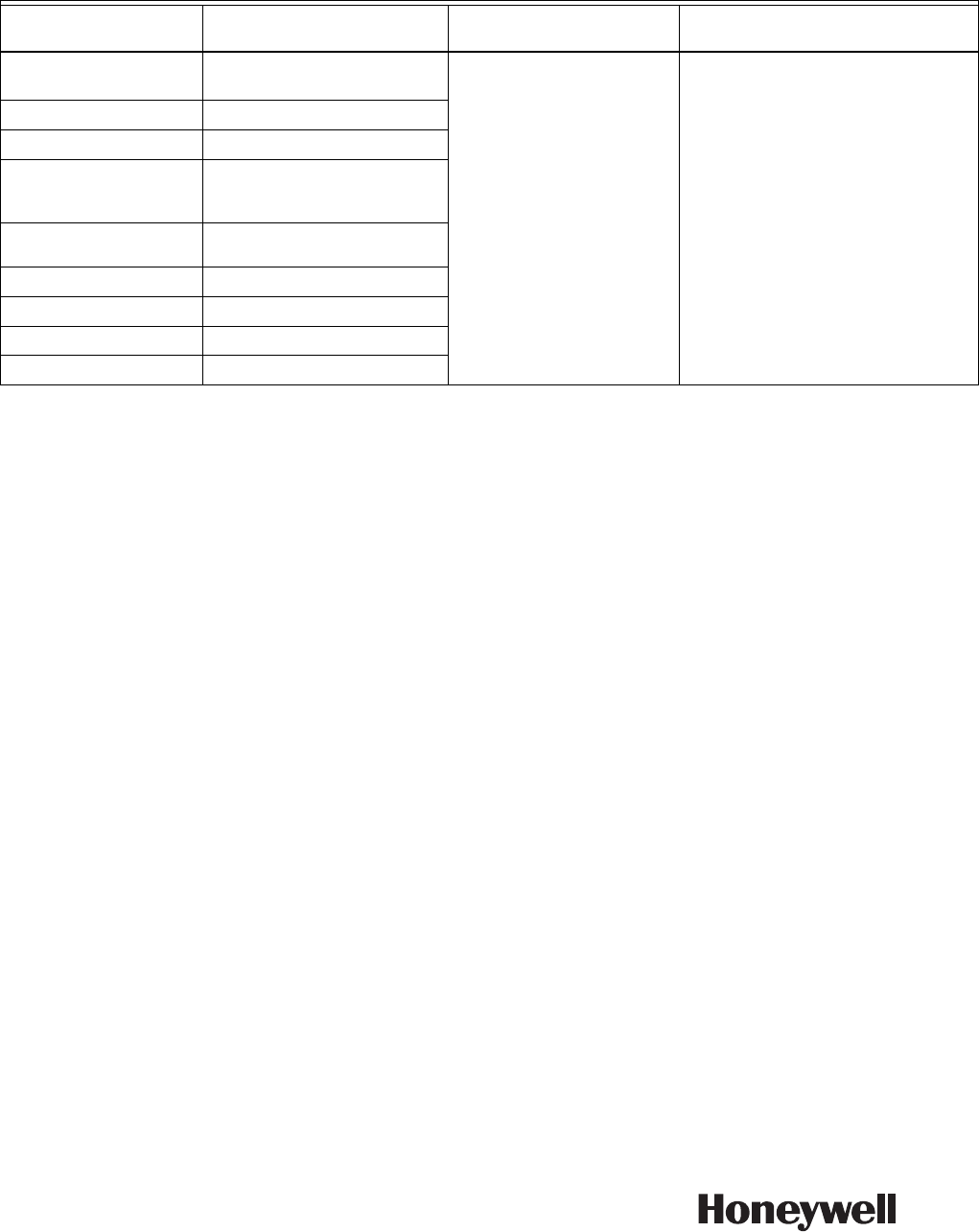

Table 3. Flame signal.

a

This minimum or stronger signal can be easily obtained if the detector is correctly installed and positioned to properly sense the

flame. Obtain this voltage before completing checkout.

b

The flame amplifiers are Ampli-Check® type.

c

Adjust slightly, or face the pipe down, or extend the sight pipe on C7012A,C applications to obtain a maximum flame signal

reading less than 5.0 volts.

d

The flame signal amplifier circuitry is tested one-half second every five seconds during burner operation and shuts down the

burner if the amplifier fails (all installations).

e

R7824C Series 2 or greater and R7847C Series 4 or greater, pulse the shutter when the flame signal reaches 1.5 Vdc.

NOTE: R7824C, Series 2 or greater, pulse shutter when sig-

nal of 1.5 Vdc is sensed. Display readings of 0.7 to

2.4 Vdc are common.

The flame signal for the pilot alone, the main burner flame

alone, and both together must be steady and a minimum of

1.25V. If the flame signal is unsteady, or less than the

minimum acceptable voltage, check the flame detector

installation and circuitry in the following procedure.

1. Check the supply voltages at terminals (L1) and L2 (N).

Make sure the master switch is closed, connections are

correct, and the power supply is of the correct voltage

and frequency and is sinusoidal.

2. Check the detector wiring for defects including:

a. Incorrect connections.

b. Wrong type of wire.

c. Deteriorated wire.

d. Open circuits.

e. Short circuits.

f. Leakage paths caused by moisture, soot or accu-

mulated dirt.

3. For a flame rod, make sure:

a. There is enough ground area.

b. The flame rod is properly located in the flame.

c. Temperature at the flame rod insulator is no greater

than 500°F (260°C).

4. For all optical detectors, clean the detector viewing

window, lens, and inside of the sight pipe as applicable.

5. With the burner running, check the temperature at the

detector. If it exceeds the detector maximum rated

temperature:

a. Add a heat block to stop conducted heat traveling

up the sight pipe.

b. Add a shield or screen to reflect radiated heat.

c. Add cooling (refer to sight pipe ventilation in the

detector Instructions).

6. Make sure that the flame adjustment is not too lean.

7. Make sure the optical detector is properly sighting the

flame.

8. If necessary, resight or reposition the detector.

9. If you cannot obtain proper operation, replace the

plug-in amplifier.

10. If you cannot yet obtain proper operation, replace the

flame detector.

IMPORTANT

If you make any changes to the flame detection

system, repeat all required Checkout tests in

Checkout section of the Instructions for the

applicable 7800 SERIES and R7140 Relay Module.

Flame Detector Flame Signal Amplifier

Minimum Acceptable

Steady dc Voltage

a

Maximum Expected dc Voltage

Flame Rod

C7012A,C

c

R7847A,B

b

1.25 Vdc 5.0 Vdc at Keyboard Display Module

or on volt-ohmmeter.

C7015A

R7848A,B

b

C7024E,F

R7824C

d,e

C7027A

C7035A

C7044A

R7849A,B

b

C7927

C7962

R7851B

b

C7915

R7852A,B

b

C7061A

R7861A

d

C7076A,D

R7886A

d

C7961E

R7851C

d