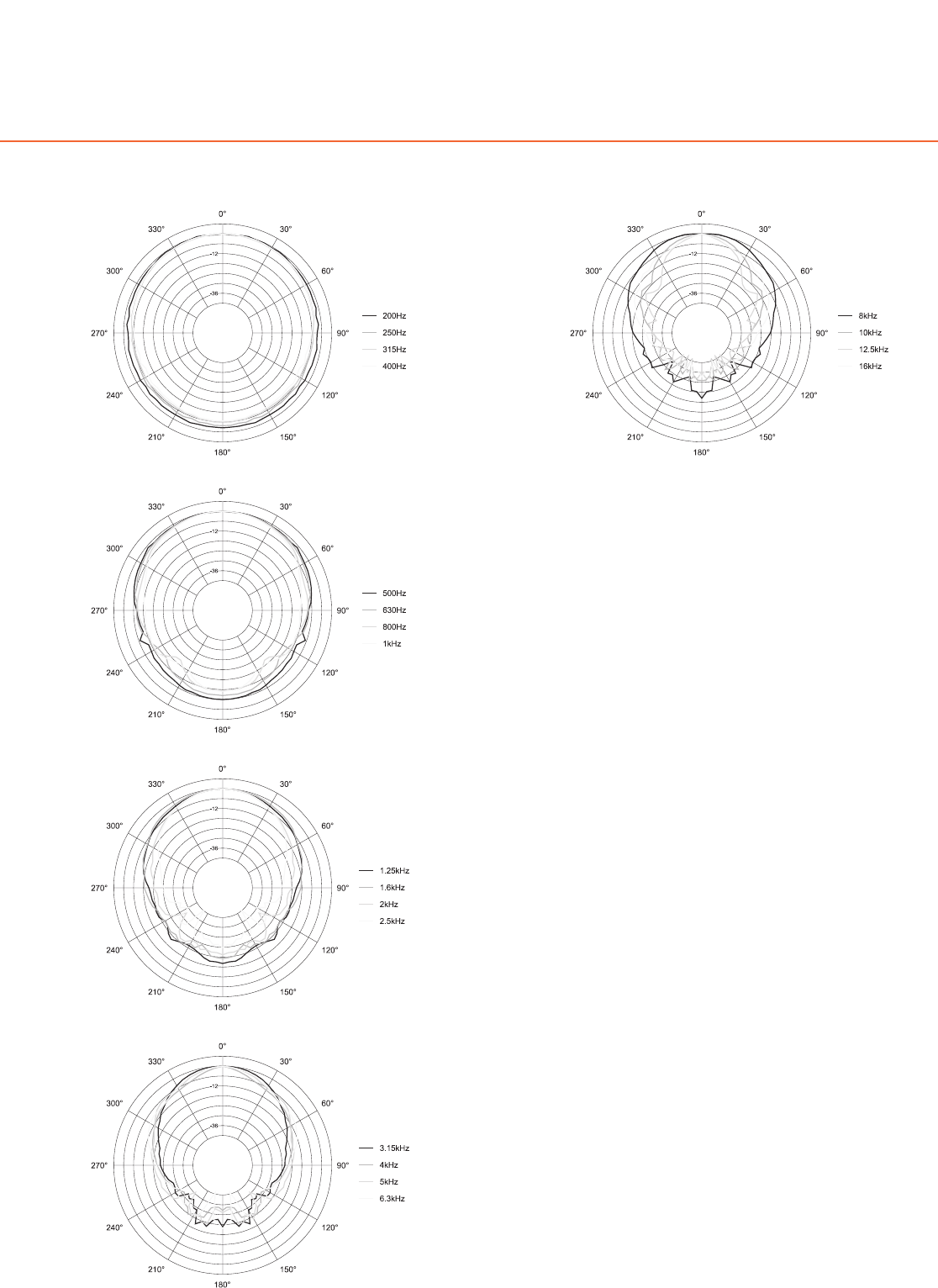

Horizontal 1/3 Octave Polars

Architectural Specifications:

The loudspeaker shall consist of a 200mm (8 in) low frequency trans-

ducer, 25mm (1 in) high frequency transducer, and frequency dividing

network installed in a ported enclosure. The low frequency voice coil

shall be 32 mm (1-1/4 in) in diameter.

Performance specifications of a typical production unit shall be as fol-

lows: Usable frequency response shall extend from 55 Hz to 15 kHz

(10 dB below rated sensitivity, in half-space, with no external equaliza-

tion). The loudspeaker shall be equipped with a transformer for use in

either 70.7V or 100V distributed-line sound systems with taps selectable

by rotary switch. Taps shall be nominally 7.5W @ 70V (15W @ 100V),

15W @ 70V (30W @ 100V), 30W @ 70V (60W @ 100V), and 60W @ 70V

(not used @ 100V). The frequency dividing network shall have a

crossover frequency of 2.8 kHz. Rated power capacity shall be at least

175 watts continuous program power, defined as 3dB above a test signal

of filtered random noise conforming to international standard IEC268-5

(shaped pink noise with a peak-to-average ratio of 6dB), for 100 contin-

uous hours duration.

The system shall be protected against damage from occassional over-

powering via full range series lamps that limits the power to the net-

work and transducers. The high frequency transducer shall be horn-

loaded to more evenly cover a nominal 90° horizontal by 90° vertical

area.

The enclosure shall be constructed of high-impact polystyrene for pro-

tection against the elements in outdoor applications, and for paintability.

The grille shall be completely zinc-coated for resistance against rusting,

shall be bake-painted black, and shall be secured via screws to keep it

in place when facing downward.

The low frequency transducer shall have a polypropelene cone and a

butyl rubber surround which shall extend seamlessly over the edge of

the speaker frame for protection against the elements. The high frequen-

cy transducer shall be constructed of polycarbonate, reinforced with a

titanium film for additional weather resistance. The system shall with-

stand Mil Spec 810 testing with specified time durations for exposure to

the following environments with no effect on its acoustical performance

or structural integrity: salt spray (method 509.3), temperature -19°C to

49°C (method 501.3 and 502.3), 95% humidity (method 507.3) and ultra-

violet (method 505.3). The system shall have a IEC 529 splashproof

rating of IP-X4.

For theft deterrence, the installation access area shall be hidden

behind a snap-out cover, and the access area shall be on the front of the

loudspeaker for ease of installation and adjustment. The loudspeaker

shall be rotatable over a minimum of ±35° in all directions via a ball-

type mounting system. The ball mechanism shall be internal to the cabi-

net to allow low-profile mounting and better stability via a short moment

arm. The logo shall be rotatable for proper orientation when the loud-

speaker is mounted horizontally or vertically.

The external wiring connectors shall be spring loaded and gold plat-

ed, and shall accept bare wire, single or dual banana-type connectors

with 19 mm (3/4 in) spacing. Overall cabinet dimensions shall be no

greater than 380 mm (15.0 in) high by 280 mm (11.0 in) wide by 220

mm (8.6 in) deep and shall weigh no more than 6.5 kg (14.3 lbs).

The finish shall be a paintable lighly textured black.

The system shall be the JBL Model Control 28T-60 with included

Invisiball

TM

mounting system.