7. If you have not yet done so, remove the front cover

(complete with control knob) of the unit by undoing

the retaining screws at the top and bottom of the

unit and lifting the cover off. The top-fixing hole is a

keyhole slot, and should be marked and drilled

first. Tighten top screw with head protruding about

10mm from wall and hook the back-plate over the

screw head. This allows for correct and accurate

alignment of your shower before marking and fixing

the bottom/side position. You may not wish to

tighten up all 3 screws at this stage as the holes

are elongated to allow for adjustment after other

connections have taken place.

WARNING! TAKE CARE NOT TO DAMAGE THE

PRINTED CIRCUIT BOARD IN ANY WAY. DURING

INSTALLATION AVOID DUST AND DEBRIS

GETTING ON IT.

8. Do not obstruct the pressure relief device found in

the back-plate slot underneath the outlet

connection (see diagram 2). Especially if silicone

sealant or similar materials are used around the

edges of the back-plate.

9. There are a number of clearly marked shields in

the shower unit. These are important for the correct operation of this shower and MUST

NOT be removed under any circumstances.

b) Plumbing (see diagram 9)

The heater should be connected to the mains cold water supply. This must have a minimum

running pressure of 100kPa, 1.0 bar (14.5 p.s.i) and a maximum pressure of 1000kPa, 10

bar (145 p.s.i).

Before connecting the pipe-work to the shower ensure that pipe-work is flushed out.

1. It is recommended that a WRAS (Water Regulations Advisory Scheme) listed isolating

valve is fitted between the rising main and the unit. This will allow the unit to be serviced

without turning off the cold water or exchanged without having to turn off the water at the

water mains stop valve.

2. The heater can be fed from a header tank provided this has a minimum head height of

10.5 metres (35ft).

3. 15mm copper or stainless steel pipe should be used alongside with a standard

compression fitting. In multiple shower installations correct pipe-work sizes should be

calculated to maintain adequate flow to each shower.

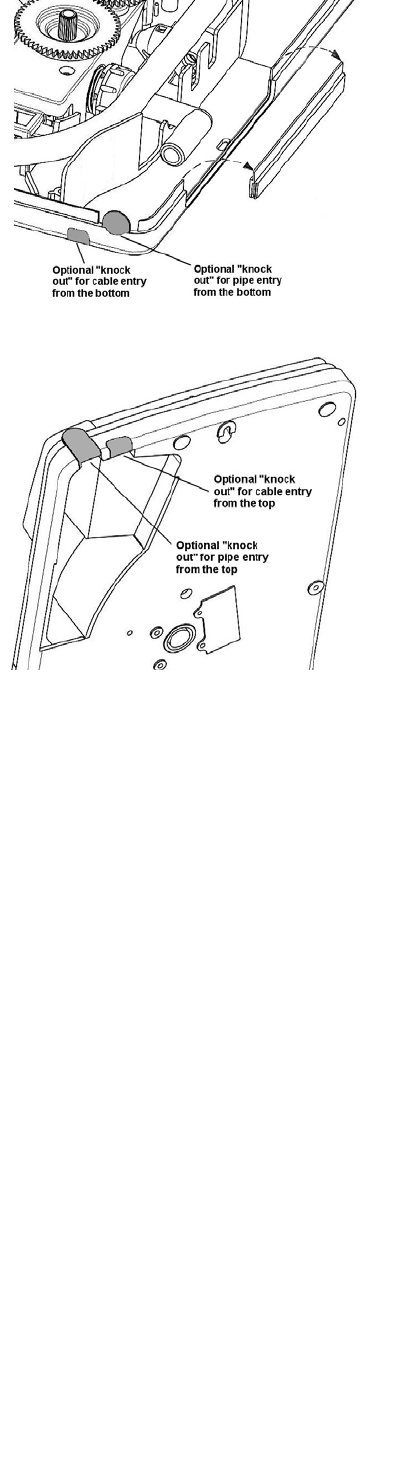

4. a) If top entry is chosen, turn the elbow 180° into the required position and fit a standard

15mm in line compression fitting. There is a removable side section, which will aid you

with this (diag.7).

b) If rear entry is chosen, turn the elbow 180° and treat it as top entry except for the fitting

of a ‘Yorkshire’ elbow in the rear channel. The removable side section will again be an

aid.

5. It is in order to use a WRAS (Water Regulations Advisory Scheme) approved sealant

sparingly whilst avoiding excess finding its way into shower operating parts.

Diagram 7

Diagram 8

7