– 24 –

PRECAUTION

1. Wipe the following components with an absorbent cotton cloth

moistened with alcohol before adjustment :

PB head Pinch roller

Idler Rubber belt

Capstan

2. Demagnetize the PB head using a head demagnetizer.

3. Be careful not to use a magnetized screwdriver.

4. After the adjustment is completed, lock the adjustment parts

using screws.

5. Unless otherwise specified, make adjustments at the specified

voltage (14.4V).

Torque Measurement

Mode Torque Meter Meter Reading

35 – 65 g • cm

FWD

CQ-102C

(0.49 – 0.90 oz • inch)

FWD 0.5 – 5.0 g • cm

Back Tension (0.01 – 0.07 oz • inch)

35 – 65 g • cm

REV

CQ-102RC

(0.49 – 0.90 oz • inch)

REV 0.5 – 5.0 g • cm

Back Tension (0.01 – 0.07 oz • inch)

60 – 200 g • cm

FF, REW CQ-201B

(0.83 – 2.78 oz • inch)

Tape Tension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A more than 60 g

REV CQ-403R (more than 2.12 oz)

SECTION 5

ELECTRICAL ADJUSTMENTS

SECTION 4

MECHANICAL ADJUSTMENTS

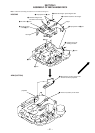

See the adjustment location from on page 28 for the adjust-

ment.

TAPE SECTION

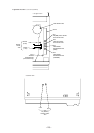

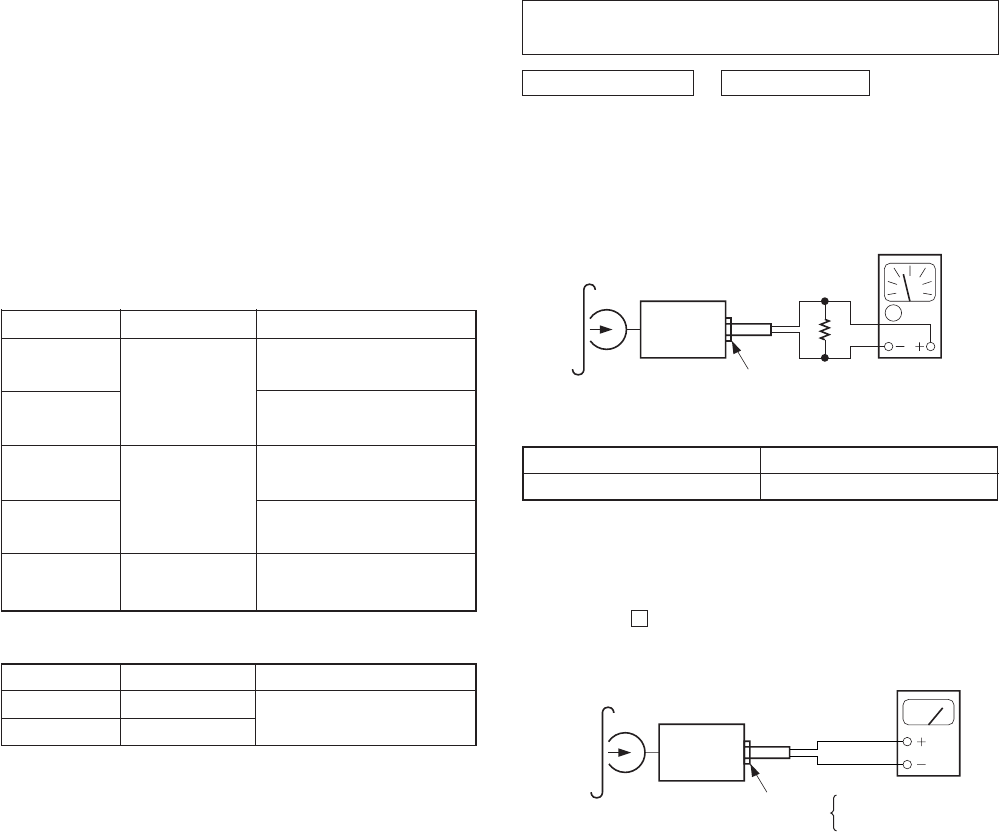

Tape Speed Adjustment

Procedure :

1. Put the set into the FWD PB mode.

Specification : Constant speed

Speed checker Frequency counter

– 1 to + 2 % 2,970 to 3,060 Hz

Adjustment Location : See page 28.

DOLBY Level Adjustment

Setting :

SHIFT n 3 (PLAY MODE) (twice) button : NR off

Procedure :

1. Put the set into the FWD PB mode.

2. Adjust RV230 (L-CH) and RV240 (R-CH) so that level meter

reading is – 6 ± 1 dB (0.35 to 0.44 V).

Adjustment Location : See page 28.

0 dB = 0.775 V

LINE OUT REAR

test tape

WS-48A

(3 kHz, 0 dB)

set

10 k

Ω

speed checker

or

frequency counte

r

main board

TP (DOLBY)

TP230 (L-CH)

TP240 (R-CH)

test tape

P-4-D400

(400 Hz, 0 dB)

set

level mete

r