Milwaukee Electric Tool Corporation

13135 West Lisbon Road

Brookfield, Wisconsin 53005

TEL: (800) 729-3878

2. Before operating the hoist, be sure to observe the following:

a. ALWAYS DISCONNECT HOIST FROM POWER SUPPLY

before removing the electrical cover or when making any

electrical connection in the hoist or pushbutton station.

b. The ground wire (green colored) of the power cable

should always be connected to a suitable ground by

means of a screw or clamp.An alligator clip does not

make a safe ground connection.

c. When installing a three-phase hoist, make only temporary

connections at the power source. Push the “UP” button

and observe the direction of the load block. If it raises, the

phasing is correct and permanent connections may be

made at the power source. If the load block lowers when

the “UP” button is pushed, release the button immediately

since the limit switches will not operate to protect the hoist

from over-travel. Reverse any two wires (except the green

ground wire) at the power source to correct the load hook

direction (phasing). Do not change connections in the

hoist or pushbutton assembly.

d. Make sure load chain is not twisted as it travels into the

hoist.

e. Operate hoist in a hanging position only. Hoist should be

permitted to align itself for a straight line pull. Do not

attempt to pull around corners.

f. Read ASME-B30.16 Safety Code for Hoists.

3. If necessary, lubricate the chain, see LUBRICATION,

page 9.

4. Check the function of the limit switches. Before placing hoist

in operation, check limit switch adjustment. Operate

pushbutton until near stop point and inch into stop limit both

top and bottom. If either switch is not correct, adjust

according to LIMIT SWITCH ADJUSTMENT, page 8.

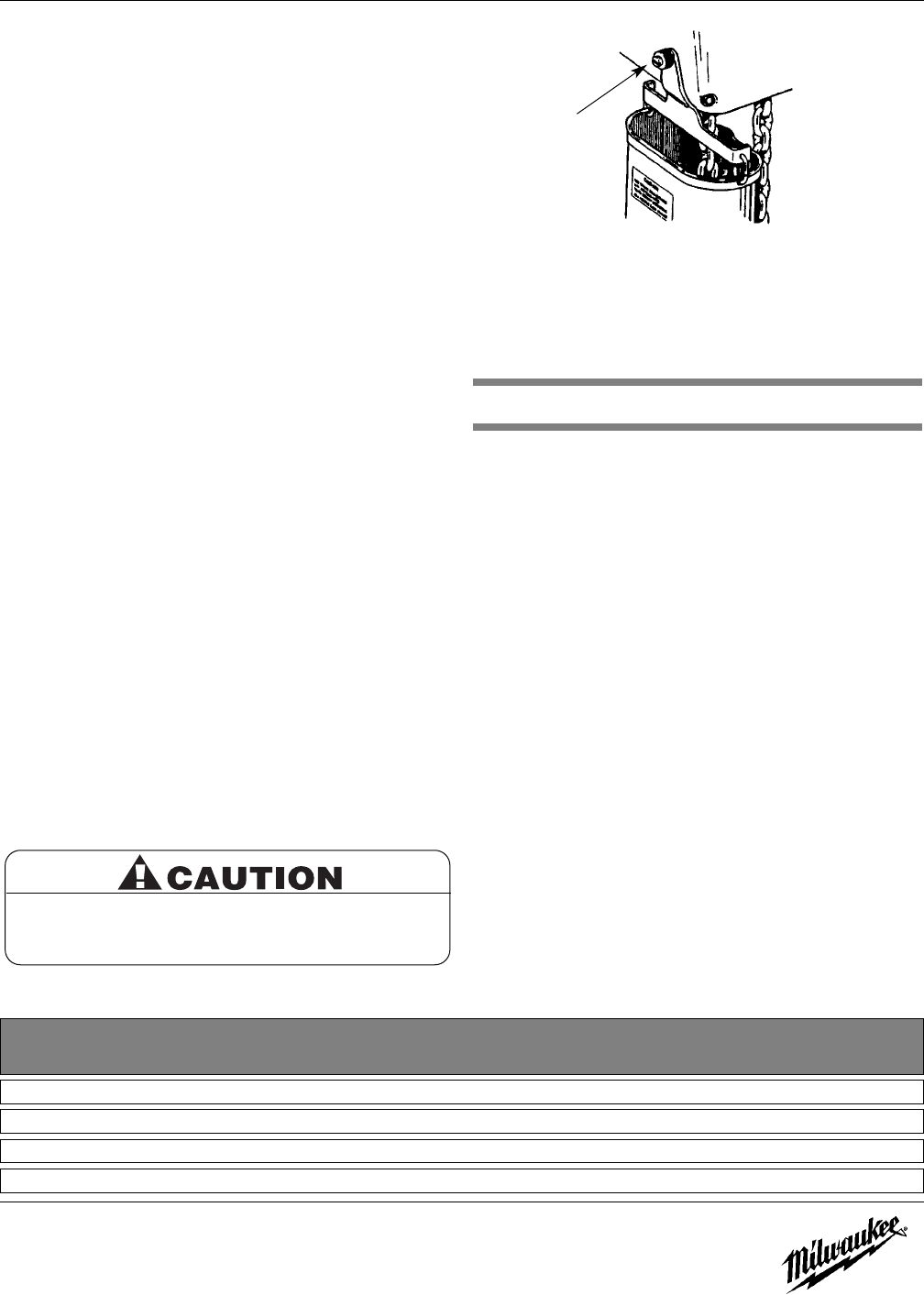

INSTALLATION OF CHAIN CONTAINER

ASSEMBLY (OPTIONAL ACCESSARY)

Refer to Figure 1 and Table 2.

1. Remove dead end screw and washers and let chain hang free.

2. Place chain container bracket flush against housing.

Replace washers and screw.Tighten securely.

3. Attach chain container to bracket with two open links and

then close the links.

4. Run the load hook down to its lowest position.Place the slack

end of the chain in the chain container.Feed the remainder of

the chain into the container by operating the hoist in the “UP”

direction to the top limit.This will permit the chain to pile

freely and eliminate the possibility of fouling which may occur

if the chain is placed in the container by hand.

OPERATION

This hoist is designed for safe operation within the limits of its

rated capacity. It is controlled with the “UP” and “DOWN”

buttons of the pushbutton station.There are many safety

features to protect the operator from injury due to failure of the

hoist. Here are some points which should be observed to

maintain safe operation.

1. Do not overload the hoist.

2. Do not make extreme side pulls with the hoist.

3. Operate the hoist only in a hanging position with

adequate support.

4. Do not “sling” the load hook and chain around the load.

Use an approved sling.

5. Be sure there are no twists in the load chain as it travels into

the hoist housing.This condition should be constantly

checked on double chain hoists because it is possible for the

load block to be “capsized” or turned over one or more times.

6. Before raising a load, always check to see that it is held

securely in the hook or sling chains, etc. Raise the load

only until the load chain is taut and then double check the

rigging before continuing to raise the load.

7. Do not stand beneath a load! Do not move a load in such a

manner as to endanger personnel.

8. Do not lower into areas where visibility is obscured unless

someone else is guiding the operation.

9. Use common sense at all times when operating a hoist.

10. Do not operate if direction of hook travel is not the same as

indicated on button being pushed.

5

Do not allow load to come in contact with chain

container. If this situation exists reset the “UP” limit

switch (See LIMIT SWITCH ADJUSTMENT, page 8) so

that hook block stops below chain container.

Standard Shipping

Hoist Lifts Chain Container Weight Dimensions in Inches

Capacity (ft) Required (lbs) Width Length Depth

Table 2 - Optional Chain Container

1/2 & 1 Ton 10, 15, & 20 48-12-0111 3 3 6½ 11½

2 Ton 10 48-12-0111 3 3 6½ 11½

2 Ton 15 48-12-0112 4 3 6½ 18½

2 Ton 20 48-12-0113 5 6 6½ 27

Figure 1 — Installing Chain Container Assembly

Dead-end Screw