14

Adjustments

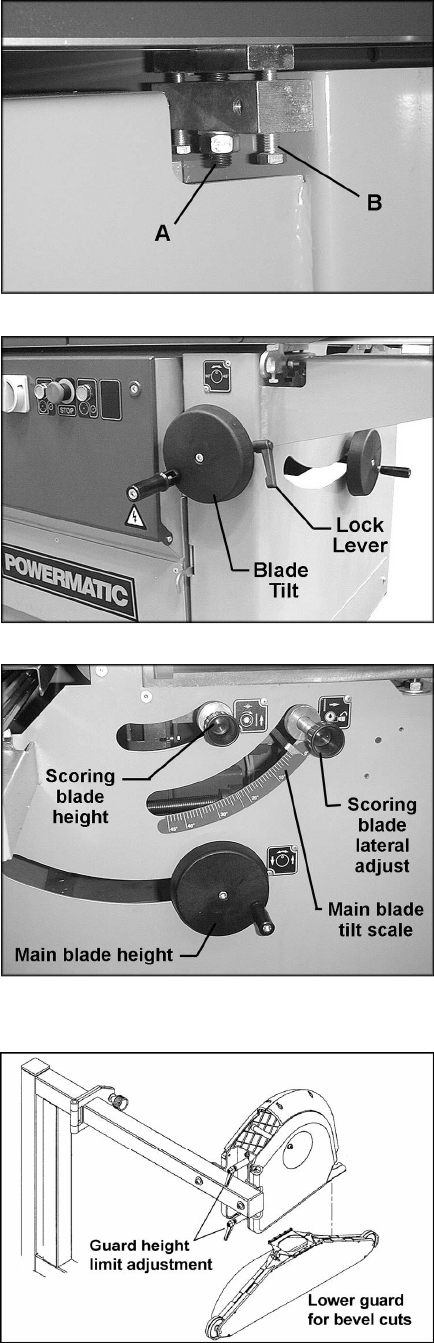

Sliding Table Parallel to Blade

The position of the sliding table relative to the

machine is factory set, but should be checked

periodically as the saw receives use. To ensure

a clean cut, the sliding table must be set parallel

to the saw blade. If adjustment is ever needed,

proceed as follows:

1. The bolts (B, Figure 20) are used to adjust

the height of the sliding table. They are pre-

set at the factory.

2. Use bolts (A, Figure 20) to correct

parallelism between sliding table and saw

blade.

Setting Main Blade (Figures 21 and 22)

Adjust the height of the saw blade with the

handwheel on the side of the machine. One turn

of the handwheel raises or lowers the blade by

2.5mm.

The blade is tilted by using the front handwheel.

The blade can be tilted at any angle between 90

and 45 degrees. After setting, lock the blade in

this position with the lock lever. The blade angle

can be read on the tilt scale.

NOTE: The 90 and 45 degree stops are pre-set

at the factory and should require no adjustment.

After setting the main blade at the desired

cutting angle, the cutting depth of the scoring

blade must be re-set.

Setting Scoring Blade

Turn the scoring blade height knob (Figure 22).

One turn raises or lowers the scoring blade by 3

mm.

Each time the main saw blade is resharpened or

replaced, the scoring blade must be adjusted

laterally to match the main blade teeth. This

must be done to ensure a clean cut free of

splintering. Lateral movement is obtained by

turning the lateral adjustment knob (Figure 22),

then locking it at the desired setting.

Setting Blade Guard

The two handles (Figure 23) are for setting the

guard height limits. Loosen a handle and slide

the bracket as needed. Both handles on the

guard should be tightened securely before

operating the panel saw.

When the arbor is tilted for a bevel cut, mount

the alternate lower guard with the convex back

(Figure 23).

Figure 20

Figure 21

Figure 22

Figure 23