18

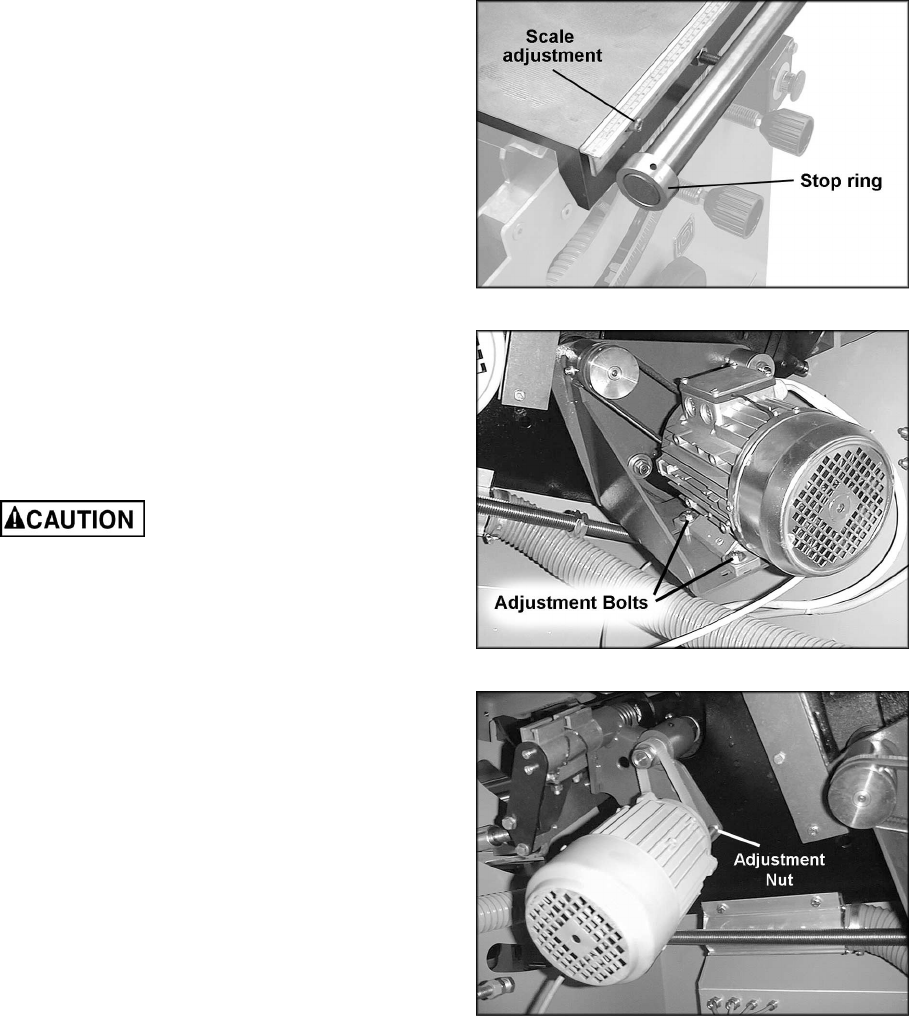

Loosen the three screws on the scale (Figure

35) and nudge the scale until it matches the cut

measurement. Make another cut to confirm the

measurement.

To avoid the fence contacting the rotating saw

blade, the stop ring must be adjusted.

Slide the fence to about 10mm from the saw

blade.

Slide the stop ring across the round guide bar

until it comes up against the casting of the

fence. Tighten the set screw on the stop ring.

Tensioning the Belt

To tension the belt on the main motor:

1. Remove the access door and loosen the

four bolts (Figure 36) which hold the motor.

2. Tension the belt by pushing the motor to the

right, and tighten the four bolts.

Make sure the belt is not

over-tensioned as this may lead to damage

to the saw arbor and belt.

To tension the belt on the scoring motor:

1. Loosen the two nuts (Figure 37) which hold

the scoring motor.

2. While pushing the motor down, tighten the

two nuts.

When replacing belts on the main or scoring

motor, make sure the belt is well positioned into

the v-groove of the pulley.

Precision Tuning Your

Panel Saw

Your HPS67 is a precision machine designed to

give accurate performance over many years.

But like all fine equipment, it can only meet the

tight tolerances required if it is tuned correctly.

Your machine has been so designed that all the

major parameters which influence the quality of

cut can be adjusted by non-technical staff.

These tuning procedures should be carried out

in the proper order, as later adjustments depend

upon the earlier being correct.

The four steps of the procedure are:

1. Free Cut from blade to sliding table

2. Free Cut from blade to rip fence

3. Square Cut

4. Scoring Saw

Figure 35

Figure 36

Figure 37