15

When bevel cutting, make

sure the appropriate blade guard has been

mounted before operating the saw.

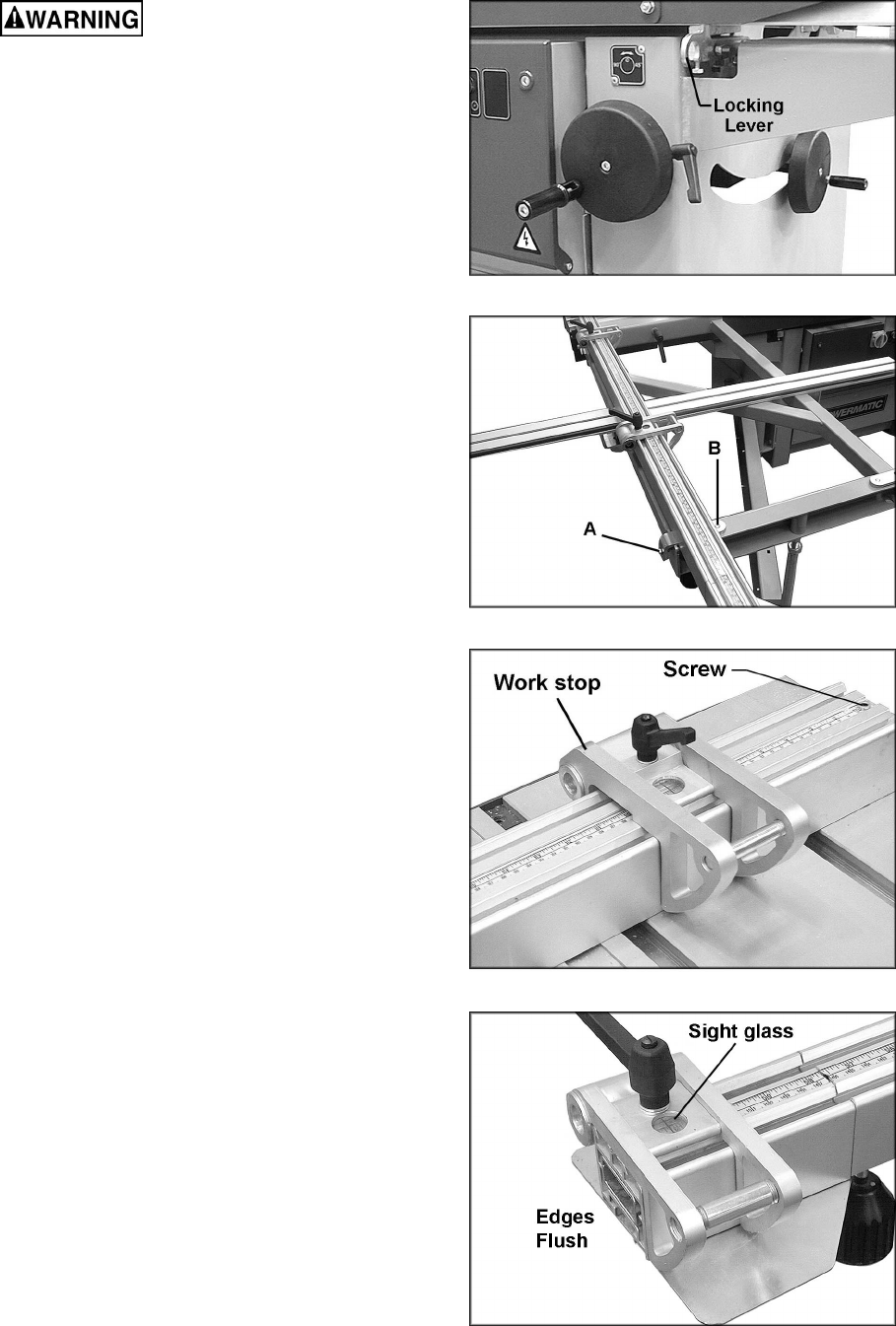

Sliding Table Lock

When loading panels and when cutting using the

rip fence, the sliding table should be locked.

To lock the sliding table, pull lever (Figure 24)

into one of the slots in the sliding table.

Over a long period of time, if many short

movements of the sliding table are made (e.g.

crosscutting solid wood) then it is possible that

the ball carrier between the upper and lower part

of the sliding table will move. This means it will

no longer be correctly positioned to allow the

sliding table to slide through its full course. The

operator will feel resistance in the sliding table

motion and the full stroke will not be achieved.

This effect can be corrected simply by pushing

the table with a few short, light pushes against

the buffer stop at the end, until the position of

the ball carrier is adjusted and the table can be

moved again along its full stroke.

Crosscut Fence

The 90-degree angle of the fence is factory set.

However, should adjustment ever be needed,

proceed as follows:

1. Loosen the two bolts (A, Figure 25).

2. Turn bolt (B, Figure 25) to open or close the

angle of the fence in relation to the saw

blade.

3. Re-tighten bolts (A, Figure 25).

Before using the first time, and each time a new

blade is installed, the scales must be calibrated.

Proceed as follows:

1. Put the stop (Figure 26) at a certain

measure and cut off a sample.

2. Measure the exact length of the sample.

Loosen the screw (Figure 26) which holds

the scale and move the scale until the

measurement corresponds to the length of

the previously cut sample. The main part of

the fence is now calibrated to the saw blade.

3. The scale on the telescopic extension of the

fence should now be checked and adjusted.

Move the other stop to the outermost edge

of the extension fence until the edge of the

stop is flush with the edge of the fence

(Figure 27). Lock the stop in position by

tightening the handle.

NOTE: DO NOT loosen the stop until the

adjustment procedure has been completed.

Figure 24

Figure 25

Figure 26

Figure 27