R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

60-2337—3

6

OPERATION

Models with Preignition Interlocks

Fig. 3 shows all contacts in the standby position (zero

seconds). The opening and closing times are shown adjacent

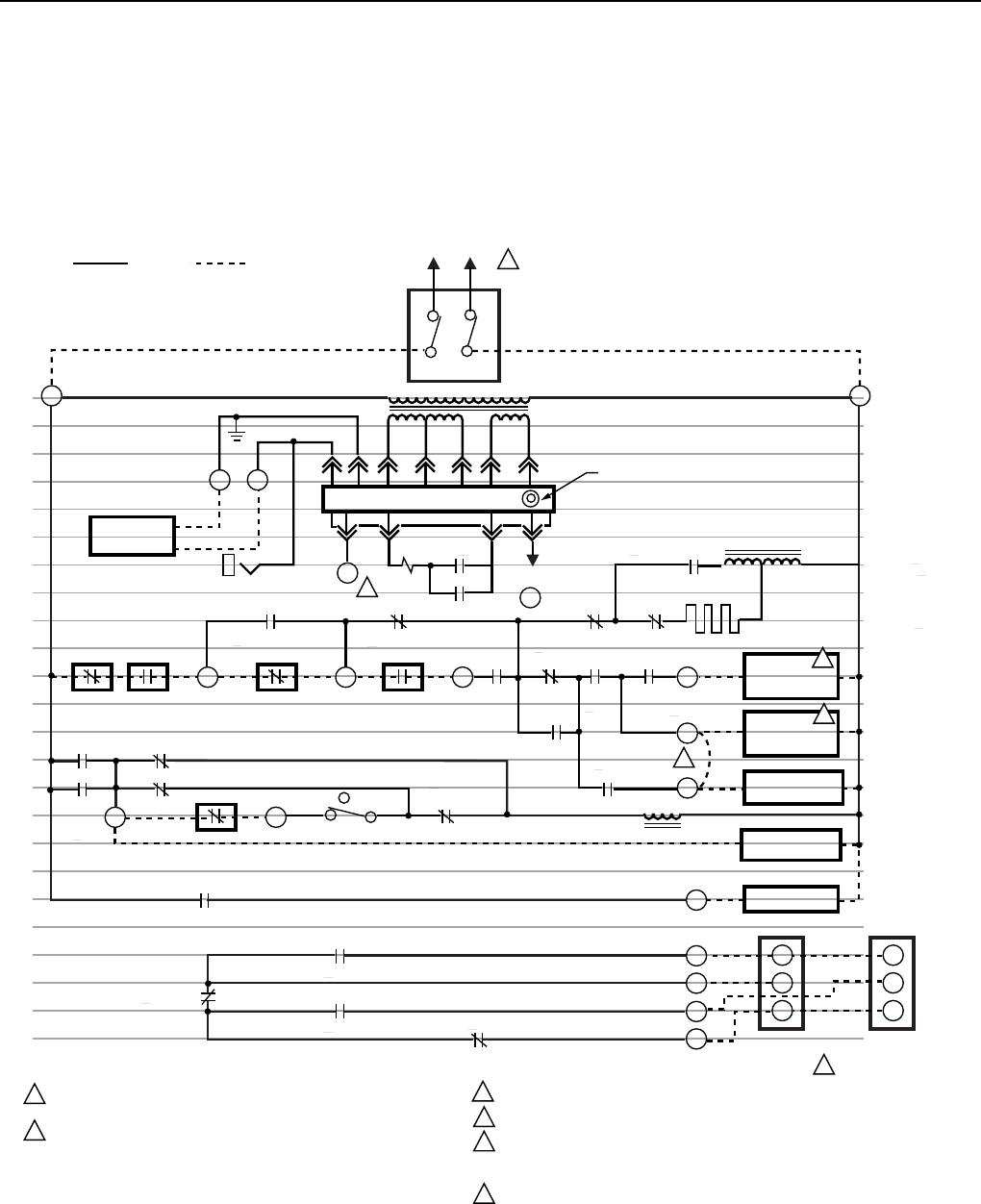

Fig. 3. Simplified schematic diagram of R4140G1015 Programmer.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

B

R

W

B

R

W

14

12

11

10

9

L1

(HOT)

L2

1

2

120V, 60 HZ

POWER SUPPLY

UNDERLINED O OR C DENOTES SNAP ACTION OF CONTACT.

A TIMER CONTACTS SNAP CLOSED.

B CONTACTS SNAP OPEN.

MASTER

SWITCH

L2

O—OPENING TIME

C—CLOSING TIME

LS DENOTES LOCKOUT SWITCH; HTR DENOTES HEATER

INTERNAL

EXTERNAL

FLAME

DETECTOR

L1

PLUG-IN AMPLIFIER

FLAME SIGNAL

METER JACK

NUMBERS BELOW

DESIGNATE LINE

LOCATIONS OF

RELAY CONTACTS.

(UNDERLINE

INDICATES A

NORMALLY CLOSED

CONTACT.)

LS - 19, 9

G

F

TIP JACK

17

4

8

13

3 9 13 5 8 12 10

1611

7

17

2K

1K

M11B

C-15 O-70

2K3

1K3

2K2

M9A

C-57.5 O-109.5

TO

TERMINAL

8

16 3 5

6

7

LIMITS

BURNER

CONTROLLER

PREIGNITION

INTERLOCKS

10 SECOND

INTERRUPTED

PILOT/IGNITION

30 SECOND

INTERRUPTED

PILOT/IGNITION

RUNNING

INTERLOCKS

(INCLUDING

AIRFLOW SWITCH)

MAIN FUEL

VALVES (S)

BURNER MOTOR

(BLOWER)

120 V ALARM

HIGH FIRE

LOW FIRE

COMMON

MODULATE

M8B O-100 C-116

M8A C-100 O-112

M10B O-4 C-45

M10A C-4 O-41

2K - 13, 9, 8

1K - 14, 14, 11

M7A

C-57.5 O-111

M7B

O-9.5 C-116

LS HTR

LS2

M2B

O-70

C-113.5

2K1

M4A

C-60

O-85

M2A

C-70

O-109.5

M6B

C-50 O-80

1K1 1K2

M1B

C-4

O-120

M3A

O-52 C-66

LOW FIRE

SWITCH

NORM

TEST

TIMER SWITCH

M5B

O-104

C-108

TIMER MOTOR

FIRING

RATE

MOTOR

SERIES 90

CONTROLLER

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

TERMINAL 17 IS USED ONLY TO DRIVE THE SHUTTER ON A C7012E OR F

OR A C7076A ULTRAVIOLET FLAME DETECTOR WITH SELF-CHECKING

FEATURE. POWER TO DRIVE THE SHUTTER IS APPLIED TO TERMINAL 17

FROM TERMINAL 8 THROUGH A SOLID STATE SWITCH IN THE R7247C

OR R7476A DYNAMIC SELF-CHECK AMPLIFIER. REFER TO SAMPLE BLOCK

DIAGRAM OF FIELD WIRING.

10 SECOND MAIN BURNER FLAME-ESTABLISHING PERIOD.

30 SECOND MAIN BURNER FLAME-ESTABLISHING PERIOD.

FOR DIRECT SPARK IGNITION (GAS OR OIL,) A JUMPER IS INSTALLED

BETWEEN TERMINALS 6 AND 7. REFER TO SAMPLE BLOCK DIAGRAM

OF FIELD WIRING FOR HOOKUP.

USE A SERIES 90 MODULATING MOTOR IF MODULATION IS REQUIRED.

M10149

LS1

6

4

5

1

2

3

4

5

6

3

R4140G1007/G1015 SCHEMATIC

(WITH/WITHOUT HEAVY DUTY COVER)

to each timer contact. Refer to Fig. 4 and the Step-by-Step

Operation section.