26 SPAN-CPT User Manual Rev 8

Chapter 3 SPAN-CPT Operation

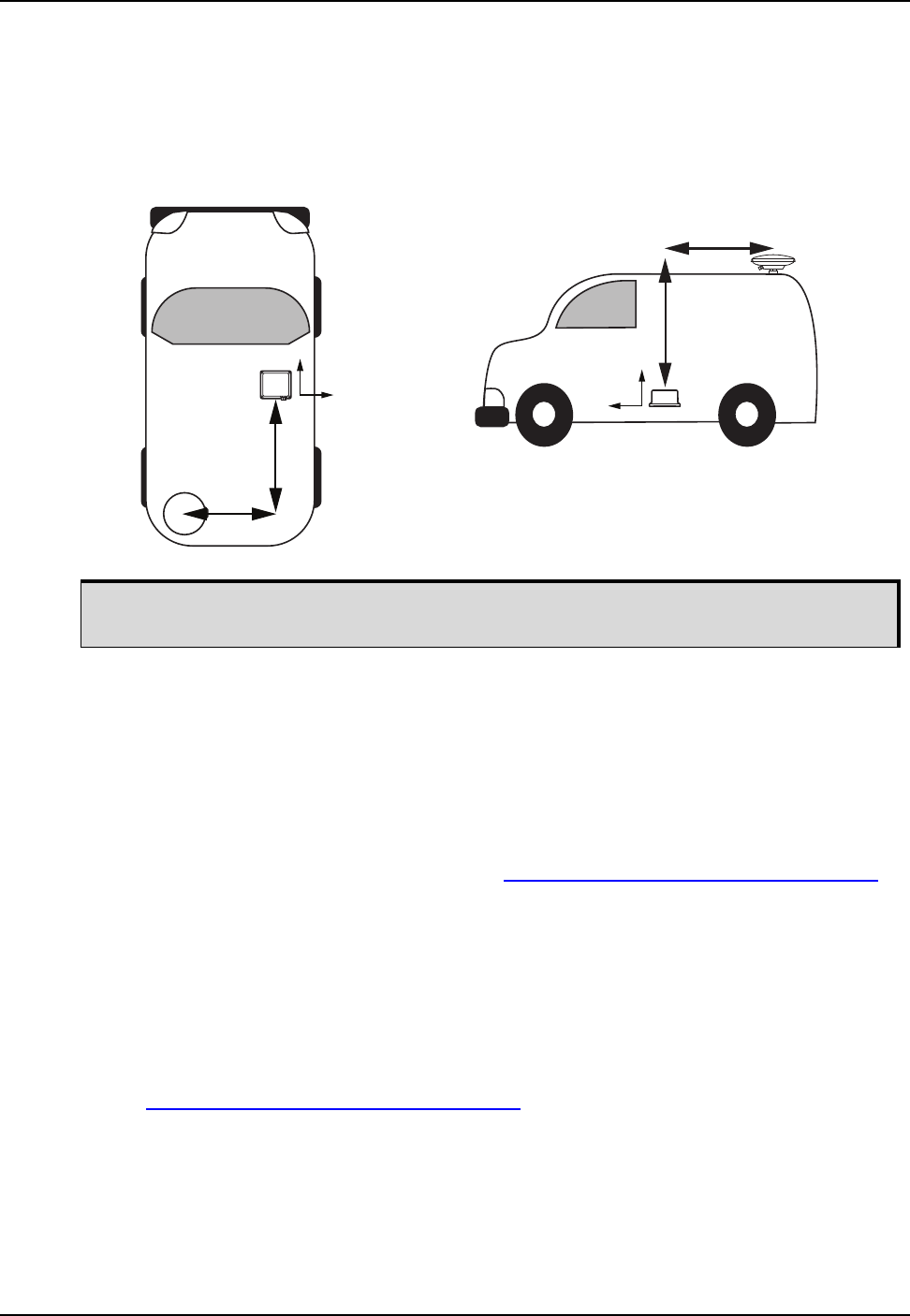

The offset between the antenna phase center and the IMU navigation center must remain constant

and be known accurately. The X, Y and Z positive directions are clearly marked on the SPAN-CPT

enclosure. The SETIMUTOANTOFFSET parameters are in metres:

SETIMUTOANTOFFSET x_offset y_offset z_offset [x_stdev] [y_stdev]

[z_stdev]

The standard deviation fields are optional and the distances are measured from the IMU navigation

center to the antenna phase center.

A typical RTK GNSS solution is accurate to a few centimetres. For the SPAN-CPT system to have

this level of accuracy, the offset must be measured to within a centimetre. Any offset error between

the two systems directly affects the output position. For example, a 10 cm error recording this offset

will result in at least a 10 cm error in the output.

3.4 Real Time Operation

SPAN-CPT operates through the OEM6 command and log interface. Commands and logs specifically

related to SPAN-CPT operation are documented in the SPAN on OEM6 Firmware Reference Manual

(OM-20000144).

Real time operation notes:

• Inertial data does not start until FINESTEERING time status is reached, and therefore, the

SPAN-CPT system does not function unless a GNSS antenna is connected with a clear view of

the sky.

• The inertial solution is computed separately from the GNSS solution. The GNSS solution is

available from the SPAN-CPT system through the GNSS specific logs even without SPAN

running. The integrated GNSS+INS solution is available through special INS logs documented in

the SPAN on OEM6 Firmware Reference Manual

(OM-20000144).

• The IMU solution is available at the maximum rate of output of the SPAN-CPT (100 Hz). Because

of this high data rate, a shorter header format was created. These shorter header logs are

defined with an S (RAWIMUSB rather than RAWIMUB). We recommend using these logs

instead of the standard header logs to save throughput on the COM port.

Status of the inertial solution can be monitored using the inertial status field in the INS logs, Table 4,

Inertial Solution Status on page 27.

This example assumes a default mounting configuration and shows an -X offset, -Y offset

and +Z offset.

Z Offset

Y Offset

Y Offset

X Offset

Y

Z

Y

X