3 - 2

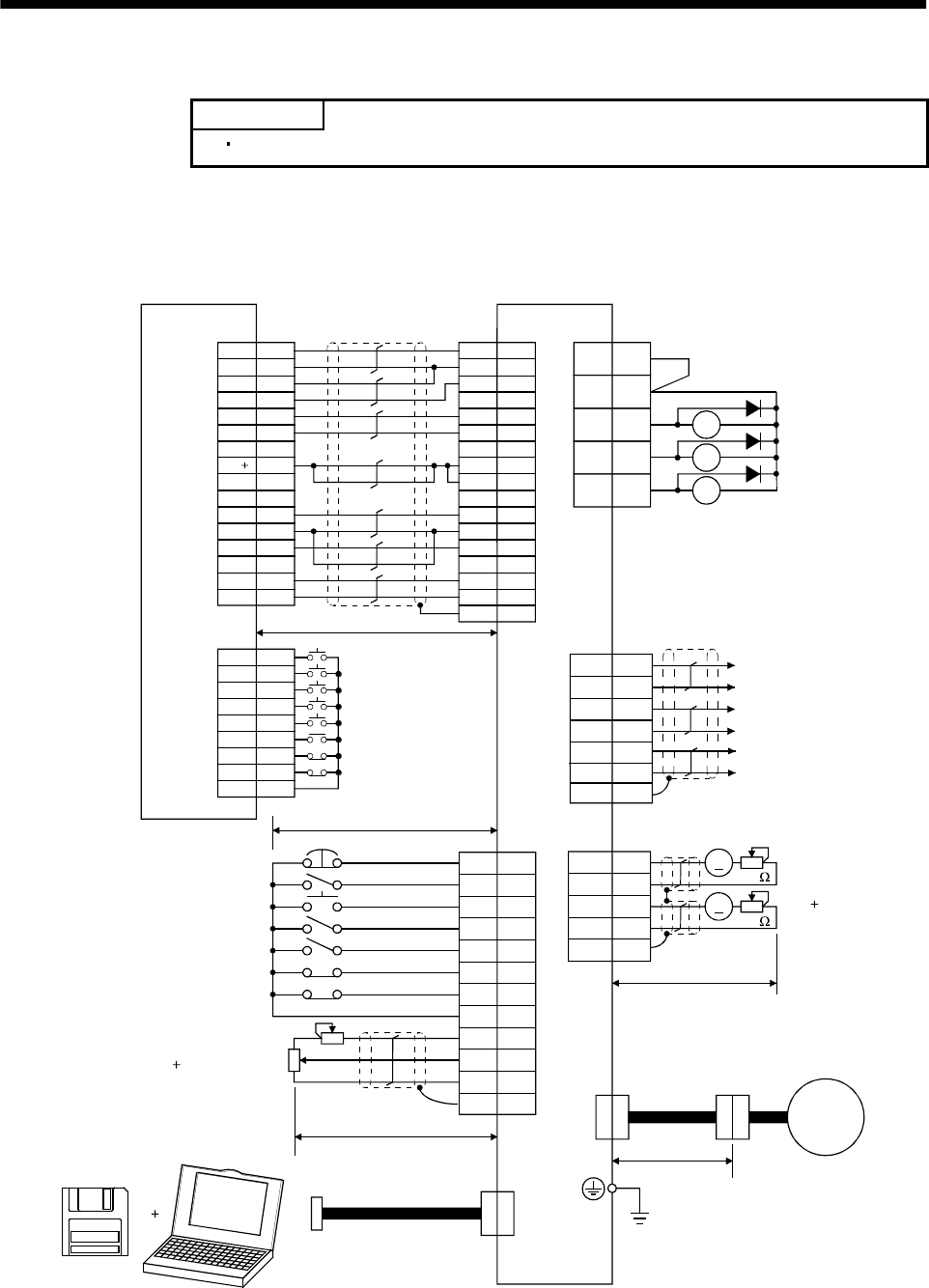

3. SIGNALS AND WIRING

3.1 Standard connection example

POINT

For the connection of the power supply system, refer to Section 3.7.1.

3.1.1 Position control mode

(1) FX-10GM

VDD

RA1

RA2

RA3

18

15

5

14

8

9

16

17

12

EMG

SON

RES

PC

TL

LSP

LSN

SD

SG

P15R

LG

10

11

ALM

19 ZSP

6TLC

CN1B

CN2

13 COM

3

TLA

CN1A

4

13

3

SD

LG

14

MO1

LG

MO2

CN3

A

A

18

19

9

4

14

1

11

9

3

10

2

8

20

START

STO

FWD

RVS

DOG

LSR

COM1

1

2

4

5

6

8

9,19

3

7

ZRN

LSF

FX-10GM

1

CN3

Positioning module

SVRDY

COM2

COM2

SVEND

COM4

PG0

24

VC

FPO

FP

COM5

RP

RP0

CLR

4

(Note 3, 6) Emergency stop

Servo-on

Reset

Proportion control

Torque limit selection

(Note 6) Forward rotation stroke end

Reverse rotation stroke end

Upper limit setting

Analog torque limit

(Note 11)

Servo configuration

software

Personal

computer

10V/max. torque

(Note 10) 2m(6.5ft) max.

10m(32ft) max.

2m(6.5ft) max.

(Note 8)

Communication cable

Servo amplifier

(Note 4, 9) (Note 4)

CN1A CN1B

1

2

12

11

14

13

7,17

8,18

5

6

9,19

16

15

3

(Note 12)

(Note 2, 5)

(Note 7)

Trouble

Zero speed

Limiting torque

(Note 4, 9)

7

6

16

Plate

17

LB

LA

LAR

SD

LBR

Encoder A-phase pulse

(differential line driver)

Encoder B-phase pulse

(differential line driver)

(Note 4, 9)(Note 4, 9)

Plate

Plate

(Note 8)

Monitor output

Max. 1mA

Reading in both

directions

10k

10k

2m (6.5ft) max.

(Note 4, 9)

Encoder cable

Servo

motor

50m (164ft) max.

(Note 4, 9)

(Note 1)

Plate

RD

COM

INP

P15R

OP

LG

COM

PP

SG

NP

CR

SD

SG

COM3

OPC

(Note 13)

5

15

LZ

LZR

Encoder Z-phase pulse

(differential line driver)