A - 4

CAUTION

Securely attach the servo motor to the machine. If attach insecurely, the servo motor may come off during

operation.

The servo motor with reduction gear must be installed in the specified direction to prevent oil leakage.

For safety of personnel, always cover rotating and moving parts.

Never hit the servo motor or shaft, especially when coupling the servo motor to the machine. The encoder

may become faulty.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the shaft may break.

When the equipment has been stored for an extended period of time, consult Mitsubishi.

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may misoperate.

Do not install a power capacitor, surge absorber or radio noise filter (FR-BIF option) between the servo

motor and servo amplifier.

Connect the output terminals (U, V, W) correctly. Otherwise, the servo motor will operate improperly.

Do not connect AC power directly to the servo motor. Otherwise, a fault may occur.

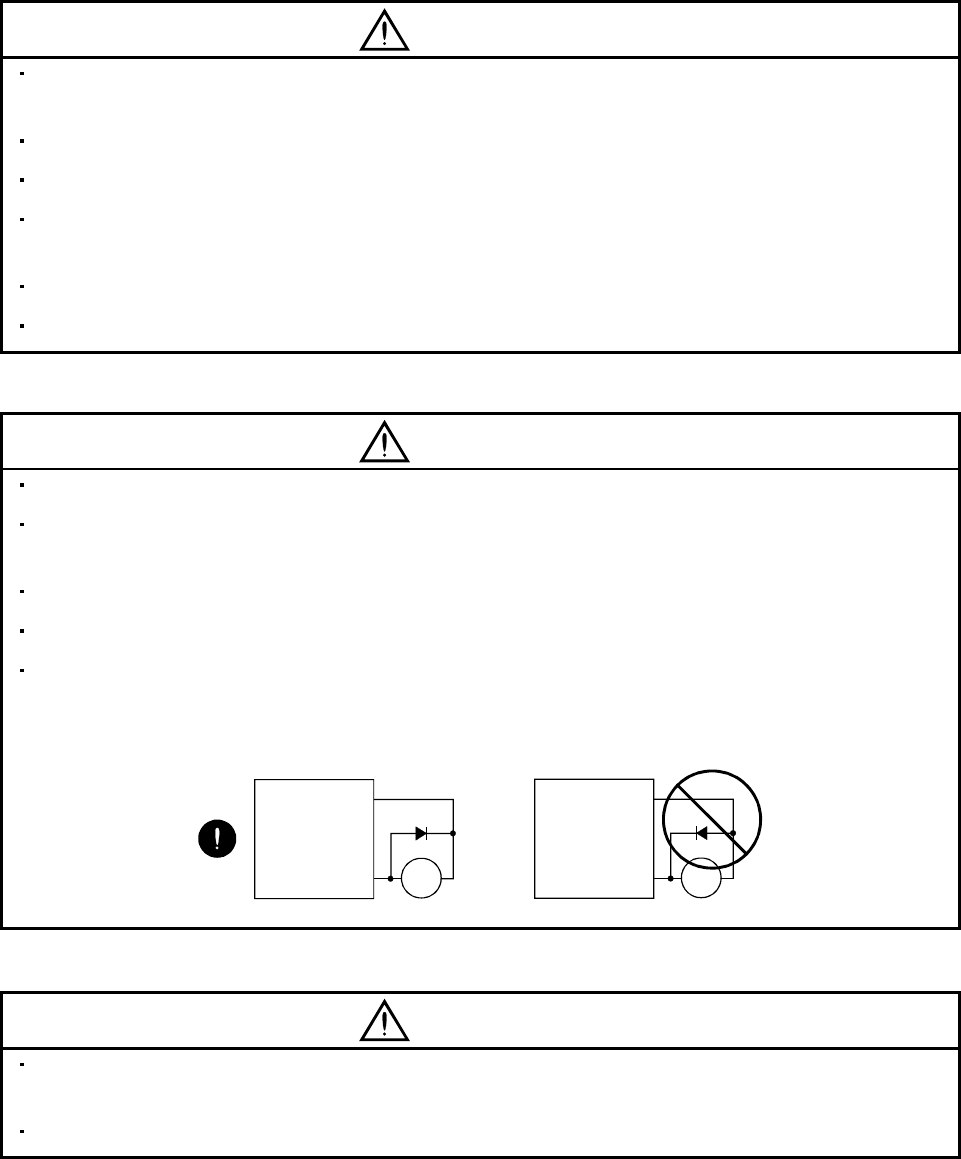

The surge absorbing diode installed on the DC output signal relay must be wired in the specified direction.

Otherwise, the emergency stop and other protective circuits may not operate.

COM

(24VDC)

Servo

Amplifier

RA

Control

output

signal

RA

Servo

Amplifier

COM

(24VDC)

Control

output

signal

(3) Test run adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to perform

unexpected operation.

The parameter settings must not be changed excessively. Operation will be insatiable.