TELEDYNE INSTRUMENTS

460L Instruction Manual Theory of Operation

05228 Rev B 55

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

10.2. Pneumatic Theory of Operation

10.2.1. Basic Pneumatic Flow And Flow Control

O

3

Measurement Cell

Particulate Filter

Flow Meter

MEASURE

REFERENCE

VALVE

O

3

IN

Exhaust

Out

Monitor Enclosure

PUMP

Flow Meter Valve

1

3

2

O

3

Scrubber

O

3

DESTRUCT

(Optional)

Gas

Pressure Sensor

ABSORPTION TUBE

Measure Cycle Gas Path

Reference Cycle Gas Path

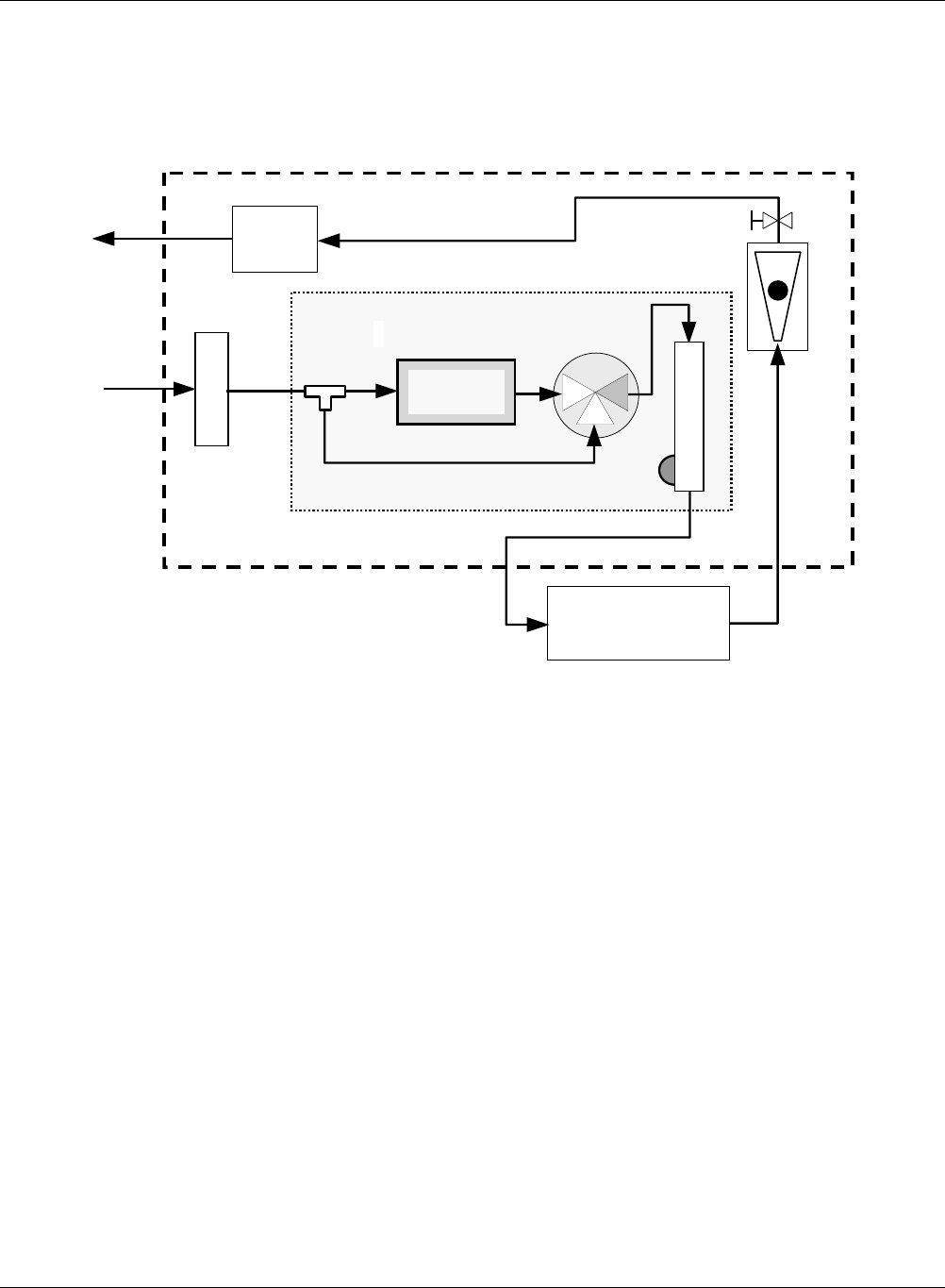

Figure 10-3 460L Internal Pneumatic Diagram – Basic Configuration

10.2.2. Internal Pump and Flow Control

Air flow through the M460L O

3

Monitor is supplied by a single-diaphragm, brushless DC pump that

pulls air though the monitor. Since diaphragm pumps necessarily heat and compress the air they

are pumping and since both temperature and pressure fluctuations can effect the O

3

measurement, the pump is placed down stream from the measurement cell to avoid any

inadvertent effects resulting from the pumping action.

An adjustable needle-restrictor valve and flow gauge, located on the front panel of the monitor

allow the user to manually adjust the gas flow rate through the monitor.

Particulate Filter

To remove particles in the sample gas which might clog airways or foul the measurement cell

optics, the monitor is equipped with a glass-fiber membrane filter of 25 mm diameter with a pore

size of 1.5 microns. The filter is located inside the black housing on the bottom of the monitor.

See Section 9.1 for location and instruction for replacing the filter element.