TELEDYNE INSTRUMENTS

Theory of Operation 460L Instruction Manual

56 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

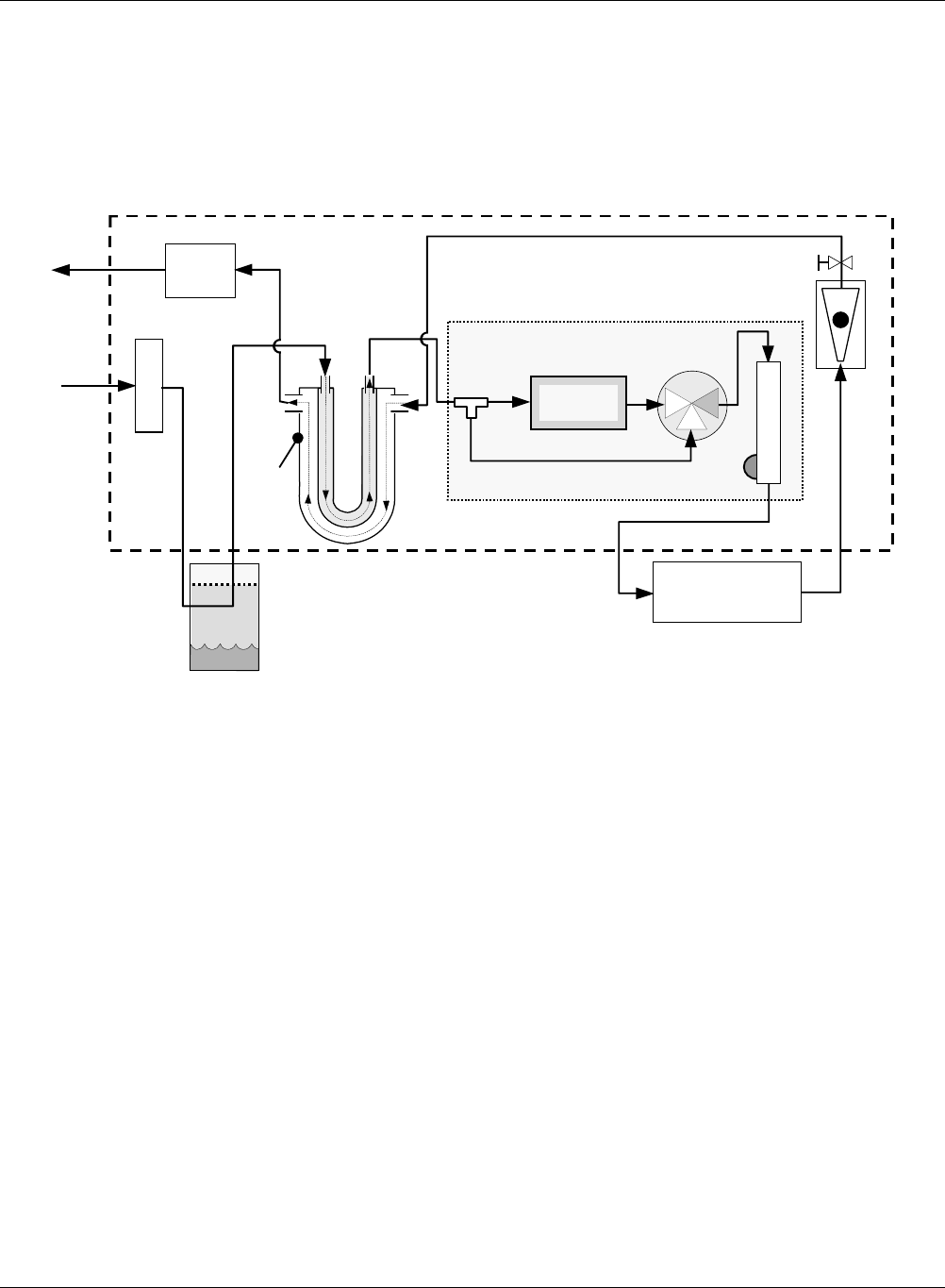

10.2.3. Optional Sample Conditioning

The source air measured by the 460L needs to be as dry as possible. Significant amounts of liquid

or vaporous water present in the source gas can foul the measurement cell optics. Also, water

absorbs O

3

and interferes with the 460L’s ability to accurately measure the O

3

in the source gas.

To counteract this problem, several optional components can be added to the 460L.

O

3

Measurement Cell

Particulate Filter

Flow Meter

MEASURE

REFERENCE

VALVE

O

3

IN

Exhaust

Out

Monitor Enclosure

PUMP

Flow Meter Valve

1

3

2

O

3

Scrubber

O

3

DESTRUCT

(Optional)

H

2

O Vapor Dryer

(Optional)

Vapor

Dryer

Purge

Line

Gas

Pressure Sensor

ABSORPTION TUBE

H

2

O

Coalescing

Filter

(Optional)

Figure 10-4 460L Internal Pneumatic Diagram with Optional Sample Conditioning

10.2.3.1. H

2

O Coalescing Filter

The first step of this drying process is to remove any liquid water from the source gas. The 460L

uses a Teflon

®

membrane, coalescing filter to accomplish this. This filter works in two ways. First,

droplets of water that are large enough to precipitate out of the air on their own simply fall to the

bottom of the filters container. Second, smaller droplets, small enough to stay combined and

bourn along with the air encounter the Teflon

®

membrane (47 mm diameter; 20 micron pore size)

at the top of the filter, and because Teflon

®

is inherently water repellent, these tiny droplets

collect along the Teflon

®

fibers combining and growing until they are large enough to drip down

into the reservoir.

10.2.3.2. H

2

O Vapor Dryer

Once all of the liquid water is removed from the source gas, a separate, Perma Pure

®

single tube

permeation tube dryer removes any vaporous water still present. The dryer consists of a single

tube of Nafion

®

, a co-polymer similar to Teflon

®

that absorbs water very well but not other

chemicals. The Nafion

®

tube is mounted within an outer, flexible plastic tube. As gas flows

through the inner Nafion

®

tube, water vapor is absorbed into the membrane walls. The absorbed

water is transported through the membrane wall and evaporates into the dry purge gas flowing

through the outer tube, countercurrent to the gas in the inner tube. This process is called

pervaporation and is driven by the humidity gradient between the inner and outer tubes as well as

the flow rates and pressure difference between inner and outer tubing.