3 - 7

3. SIGNALS AND WIRING

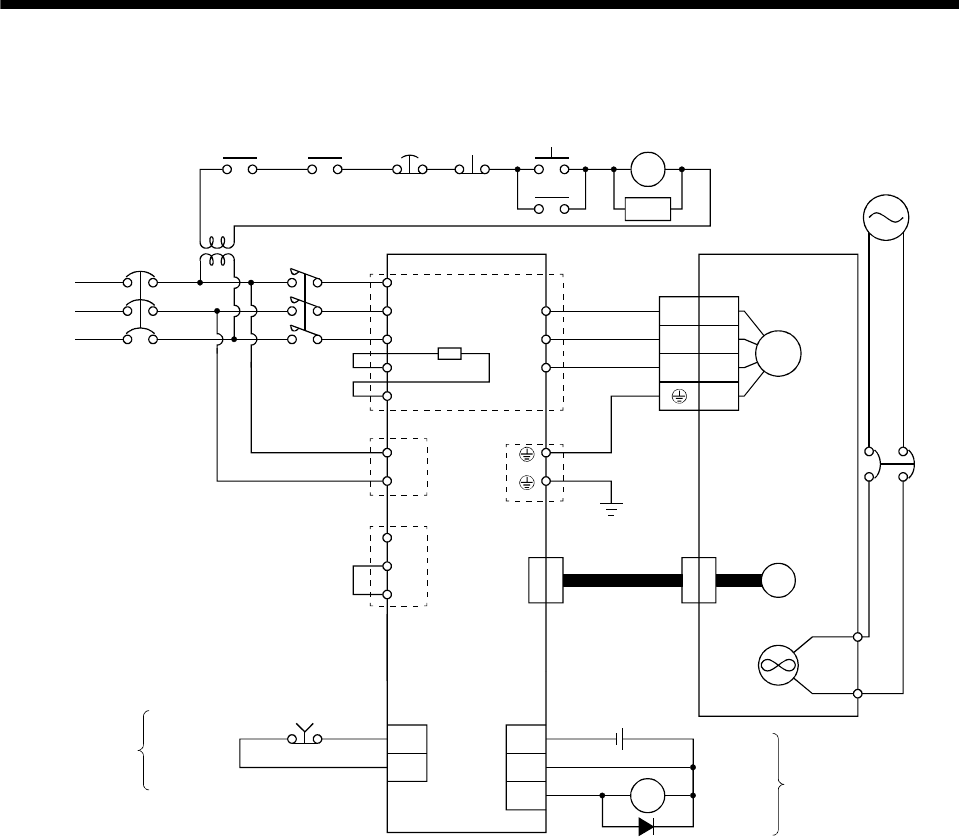

(6) MR-J3-350B4 to MR-J3-700B4

EM1

NFB MC

L

1

L

2

L

3

ALM RA1

C

DICOM

DOCOM

P

U

V

W

(Note 2)

(Note 1)

TE1

PE

U

V

W

2

3

4

1

M

Motor

Encoder

CN2

24VDC

(Note 3)

Encoder cable

(Note 6)

DOCOM

Forced stop

CN3CN3

OFF

Forced

stop

ON

MC

MC

SK

(Note 4)

Alarm

RA1

Controller

forced stop

RA2

Servo amplifier Servo motor

(Note 5)

Trouble

(Note 4)

(Note 5)

3-phase

380 to

480VAC

L11

L

21

TE2

P1

P

2

N

TE3

Built-in

regenerative

resistor

(Note 7)

Stepdown

transformer

Cooling fan

(Note 8)

Power supply

of Cooling fan

BU

BV

NFB

Note 1. Always connect P1 and P2. (Factory-wired.) When using the power factor improving DC reactor, refer to section 11.13.

2. When using the regenerative option, refer to section 11.2.

3. For the encoder cable, use of the option cable is recommended. Refer to section 11.1 for selection of the cable.

4. If deactivating output of trouble (ALM) with parameter change, configure up the power supply circuit which switches off the

magnetic contactor after detection of alarm occurrence on the controller side.

5. For the sink I/O interface. For the source I/O interface, refer to section 3.7.3.

6. Refer to section 3.10.

7. Stepdown transformer is required for coil voltage of magnetic contactor more than 200V class.

8. A cooling fan is attached to the HA-LP6014 and the HA-LP701M4 servo motors. For power supply specification of the cooling

fan, refer to section 3.10.2 (3) (b).