3 - 27

3. SIGNALS AND WIRING

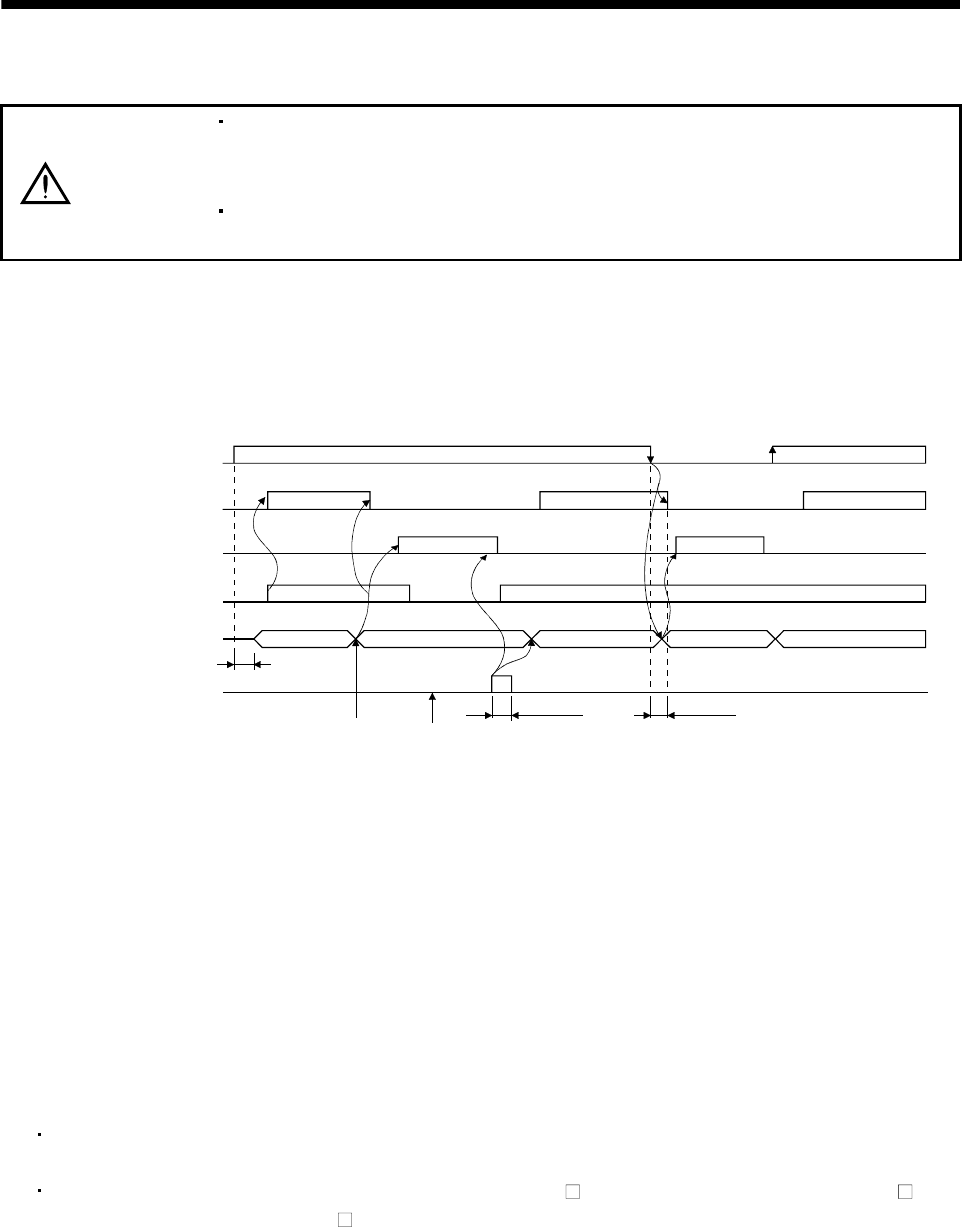

3.6 Alarm occurrence timing chart

CAUTION

When an alarm has occurred, remove its cause, make sure that the operation

signal is not being input, ensure safety, and reset the alarm before restarting

operation.

As soon as an alarm occurs, make the Servo off status and interrupt the main

circuit power.

When an alarm occurs in the servo amplifier, the base circuit is shut off and the servo motor is coated to a stop.

Switch off the main circuit power supply in the external sequence. To deactivate the alarm, power the control

circuit off, then on or give the error reset or CPU reset command from the servo system controller. However,

the alarm cannot be deactivated unless its cause is removed.

ON

OFF

ON

OFF

ON

OFF

NO

YES

ON

OFF

1s

NO

YES

Main circuit

Control circuit

power

Base circuit

Dynamic brake

Servo-on command

(from controller)

Alarm

Reset command

(from controller)

Valid

Invalid

Alarm occurs.

Remove cause of trouble.

50ms or more 60ms or more

NO

Brake operation

Brake operation

Power on

Power off

(Note)

Note. Switch off the main circuit power as soon as an alarm occurs.

(1) Overcurrent, overload 1 or overload 2

If operation is repeated by switching control circuit power off, then on to reset the overcurrent (32), overload

1 (50) or overload 2 (51) alarm after its occurrence, without removing its cause, the servo amplifier and

servo motor may become faulty due to temperature rise. Securely remove the cause of the alarm and also

allow about 30 minutes for cooling before resuming operation.

(2) Regenerative alarm

If operation is repeated by switching control circuit power off, then on to reset the regenerative (30) alarm

after its occurrence, the external regenerative resistor will generate heat, resulting in an accident.

(3) Instantaneous power failure

Undervoltage (10) occurs when the input power is in either of the following statuses.

A power failure of the control circuit power supply continues for 60ms or longer and the control circuit is

not completely off.

The bus voltage dropped to 200VDC or less for the MR-J3- B, to 158VDC or less for the MR-J3- B1, or

to 380VDC or less for the MR-J3-

B4.