5 - 14

5. PARAMETERS

Class No. Symbol Name and Function

Initial

Value

Unit

Setting

Range

Control

Mode

39 VDC Speed differential compensation:

Used to set the differential compensation.

Made valid when the proportion control signal is switched on.

980 0

to

1000

P x S

40 For manufacturer setting

Do not change this value by any means.

0000h

P x S x T41 *DIA Input signal automatic ON selection:

Used to set automatic ON of SON, LSP and LSN.

0

Servo on signal (SON) input selection

0: Switched on/off by external input.

1: Switched on automatically in servo:

amplifier.

(No need of external wiring)

0: Switched on/off by external input.

1: Switched on automatically in servo

amplifier.

(No need of external wiring)

0: Switched on/off by external input.

1: Switched on automatically in servo

amplifier.

(No need of external wiring)

Reverse rotation stroke end signal (LSN)

input selection

Forward rotation stroke end signal

(LSP) input selection

0000

0000h

to

0111h

P x S

P/S

S/T

T/P

Expansion parameters

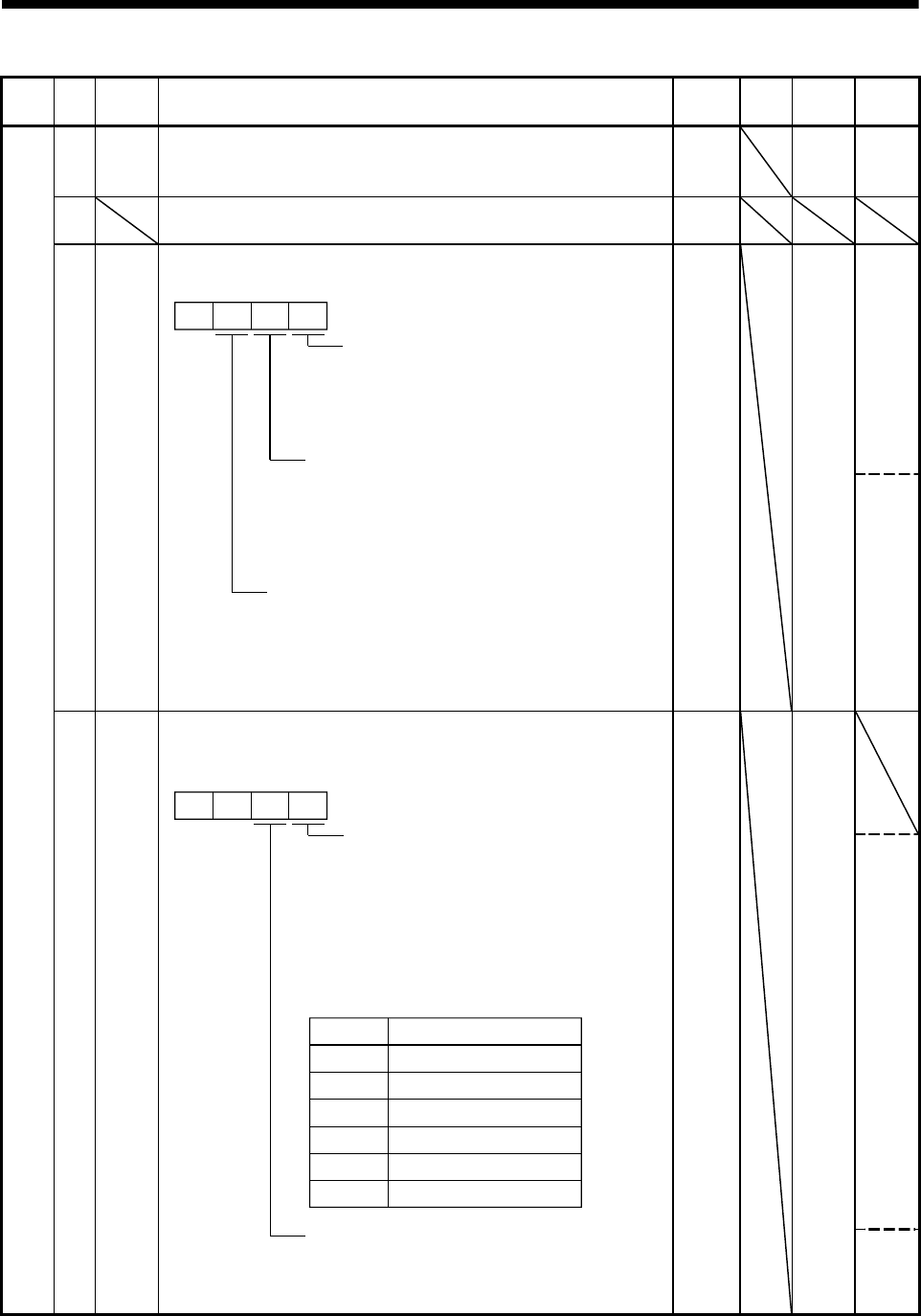

42 *DI1 Input signal selection 1:

Used to assign the control mode changing signal input pins and to set

the clear signal.

Control change signal (LOP) in-

put pin assignment

Used to set the control mode

change signal input connector

pins. Note that this parameter is

made valid when parameter No.

0 is set to select the position/spe-

ed, speed/torque or torque/posi-

tion change mode.

Set Value

0

1

2

Connector Pin No.

CN1B-5

CN1B-14

CN1A-8

3 CN1B-7

00

Clear signal (CR) selection

0: Droop pulses are cleared on the

leading edge.

1: Always cleared while on.

4 CN1B-8

5 CN1B-9

0003 0000h

to

0015h

P x S x T