12 - 12

12. OPTIONS AND AUXILIARY EQUIPMENT

P5

LG

P5

LG

19

11

20

12

2

MR

MRR

7

17

MDR 16 5

3

7

4

18P5

LG

MD 6

LG 1

BAT 9

SD

1

2

8

9

P5

LG

P5

LG

19

11

20

12

2

MR

MRR

7

17

MDR 16 5

3

7

4

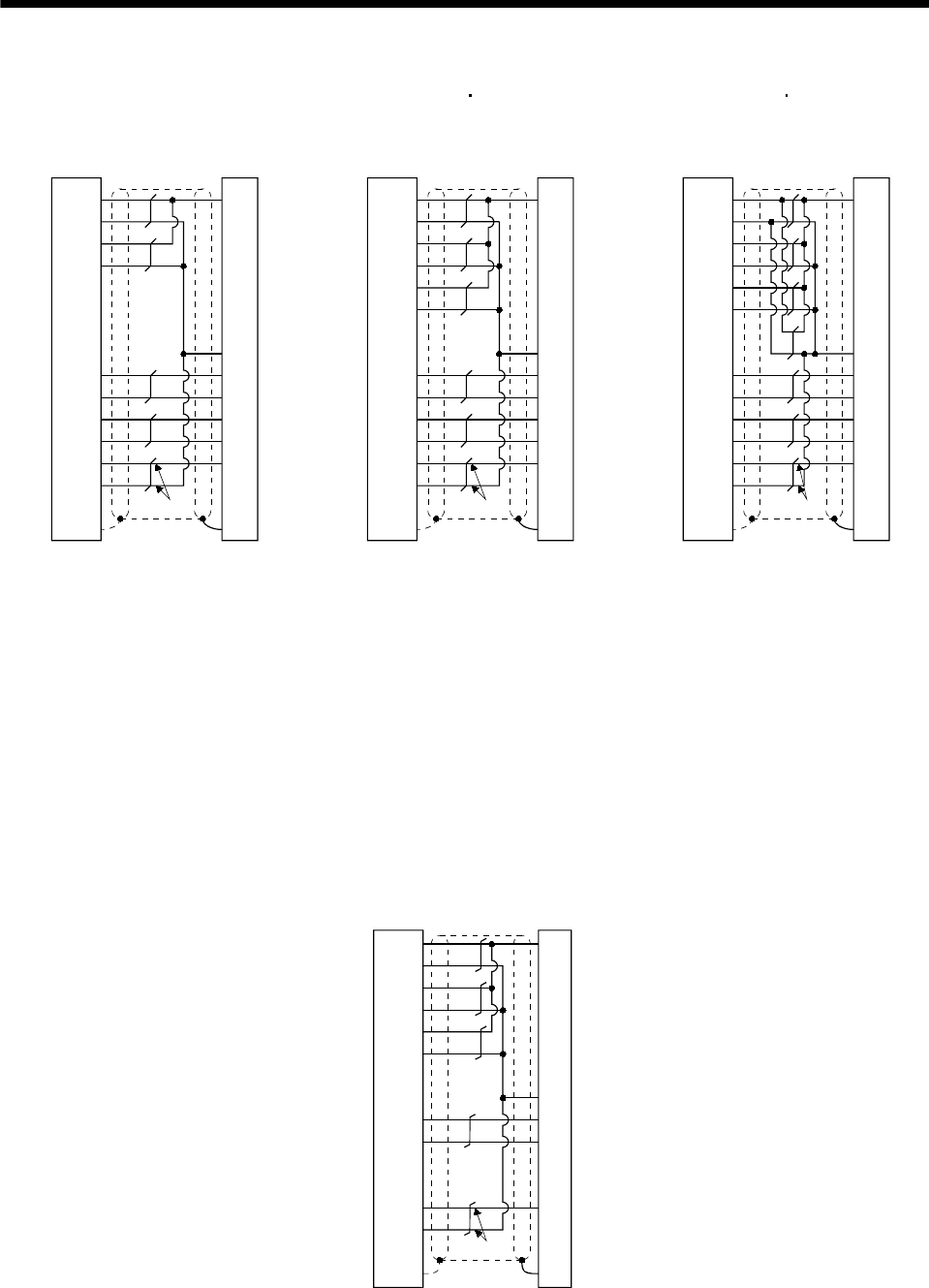

MR-JCCBL2M-L

MR-JCCBL5M-L

MR-JCCBL2M-H

MR-JCCBL5M-H

18

P5

LG

MD 6

LG 1

BAT 9

SD

1

2

8

9

P5

LG

P5

LG

19

11

20

12

2

MR

MRR

7

17

MDR 16 5

3

7

4

18P5

LG

MD 6

LG 1

BAT 9

SD

1

2

8

9

Drive unit side

Encoder side

Plate

Drive unit side

Encoder side

Plate

Drive unit side

Encoder sid

e

Plate

(Note) (Note) (Note)

Note. Always make connection for use in an absolute position detection system.

This wiring is not needed for use in an incremental system.

MR-JCCBL10M-L

MR-JCCBL20M-L

MR-JCCBL10M-H

MR-JCCBL20M-H

When fabricating an encoder cable, use the recommended wires given in Section 12.2.1 and the

MR-J2CNM connector set for encoder cable fabrication, and fabricate an encoder cable as shown

in the following wiring diagram. Referring to this wiring diagram, you can fabricate an encoder

cable of up to less than 30m (98.4ft) length including the length of the encoder cable supplied to

the servo motor.

When the encoder cable is to be fabricated by the customer, the wiring of MD and MDR is not

required.

Refer to Chapter 3 of the servo motor instruction manual and choose the encode side connector

according to the servo motor installation environment.

Note. Always make connection for use in an absolute position detection system.

This wiring is not needed for use in an incremental system.

19

11

20

12

18

2

P5

LG

P5

LG

P5

LG

7

17

9

1

MR

MRR

BAT

LG

SD

8

1

2

3

7

9

For use of AWG22

Drive unit side

Encoder side

Plate

(Note)

(3M)