12 - 25

12. OPTIONS AND AUXILIARY EQUIPMENT

12.2 Auxiliary equipment

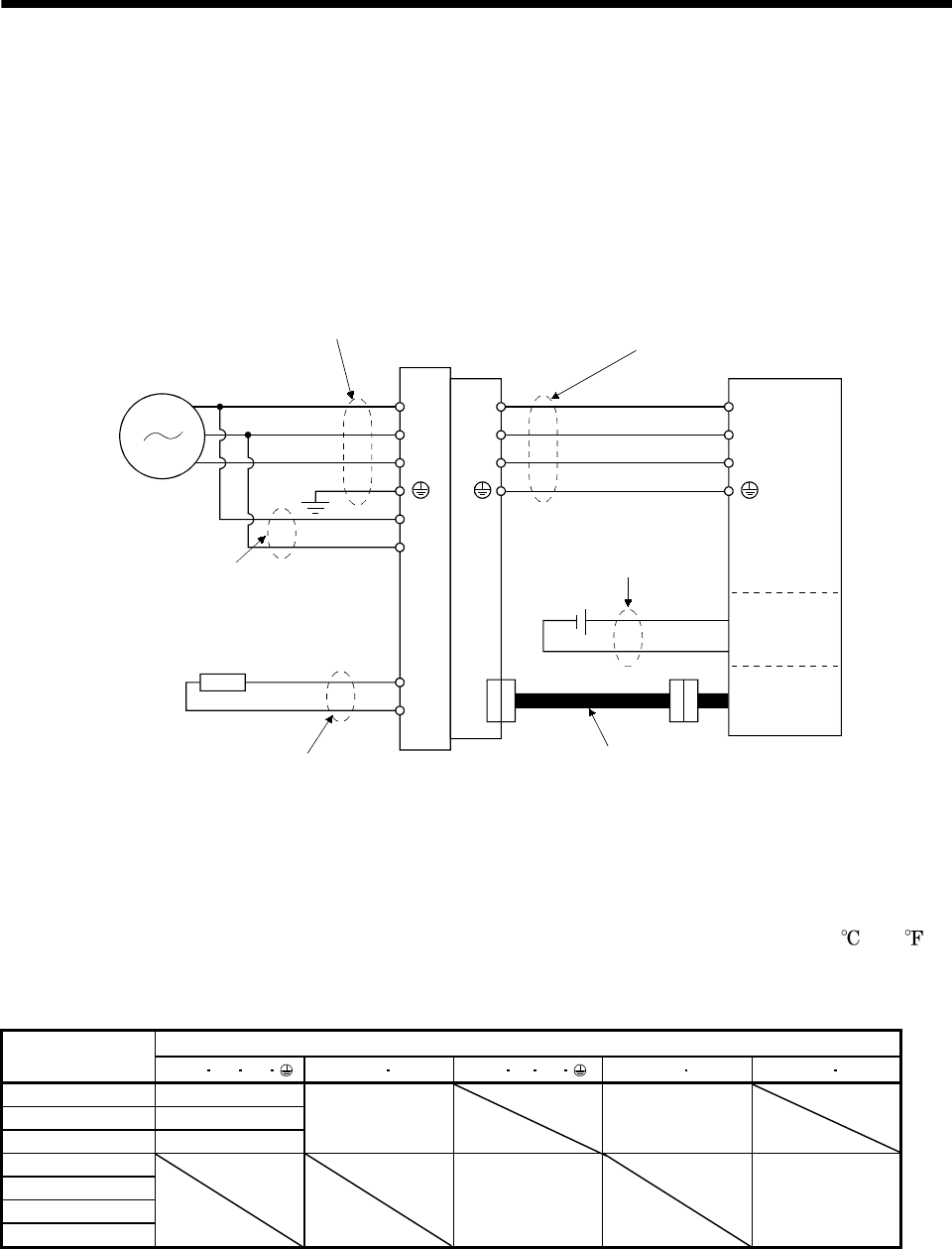

Always use the devices indicated in this section or equivalent. To comply with the EN Standard or UL/C-

UL(CSA) Standard, use the products which conform to the corresponding standard.

12.2.1 Recommended wires

(1) Wires for power supply wiring

The following diagram shows the wires used for wiring. Use the wires given in this section or

equivalent.

C

P

U

V

W

L

11

L21

B1

B2

U

V

W

L

1

L

2

L

3

CN2

1) Main circuit power supply lead

Power supply

3) Motor power supply lead

Servo motor

Encoder cable (refer to Section 12.1.2)

4) Regenerative brake option lead

5) Electromagnetic

brake lead

2) Control circuit power supply lead

Regenerative brake option

Motor

Electro-

magnetic

brake

Encoder

Base unit

Drive unit

(Earth)

The following table lists wire sizes. The wires used assume that they are 600V vinyl wires and the

wiring distance is 30m(98.4ft) max. If the wiring distance is over 30m(98.4ft), choose the wire size in

consideration of voltage drop.

The servo motor side connection method depends on the type and capacity of the servo motor. Refer to

Section 3.5.3.

To comply with the UL/C-UL (CSA) Standard, use UL-recognized copper wires rated at 60

(140 ) or

more for wiring.

Table 12.1 Recommended wires

Wires [mm

2

]

Unit

1) L

1 L2 L3 2) L11 L21 3) U V W 4) P C5) B1B2

MR-J2M-BU4 2 (AWG14)

MR-J2M-BU6 3.5 (AWG12)

MR-J2M-BU8 5.5 (AWG10)

2 (AWG14) 2 (AWG14)

MR-J2M-10DU

MR-J2M-20DU

MR-J2M-40DU

MR-J2M-70DU

1.25 (AWG16)

1.25 (AWG16)