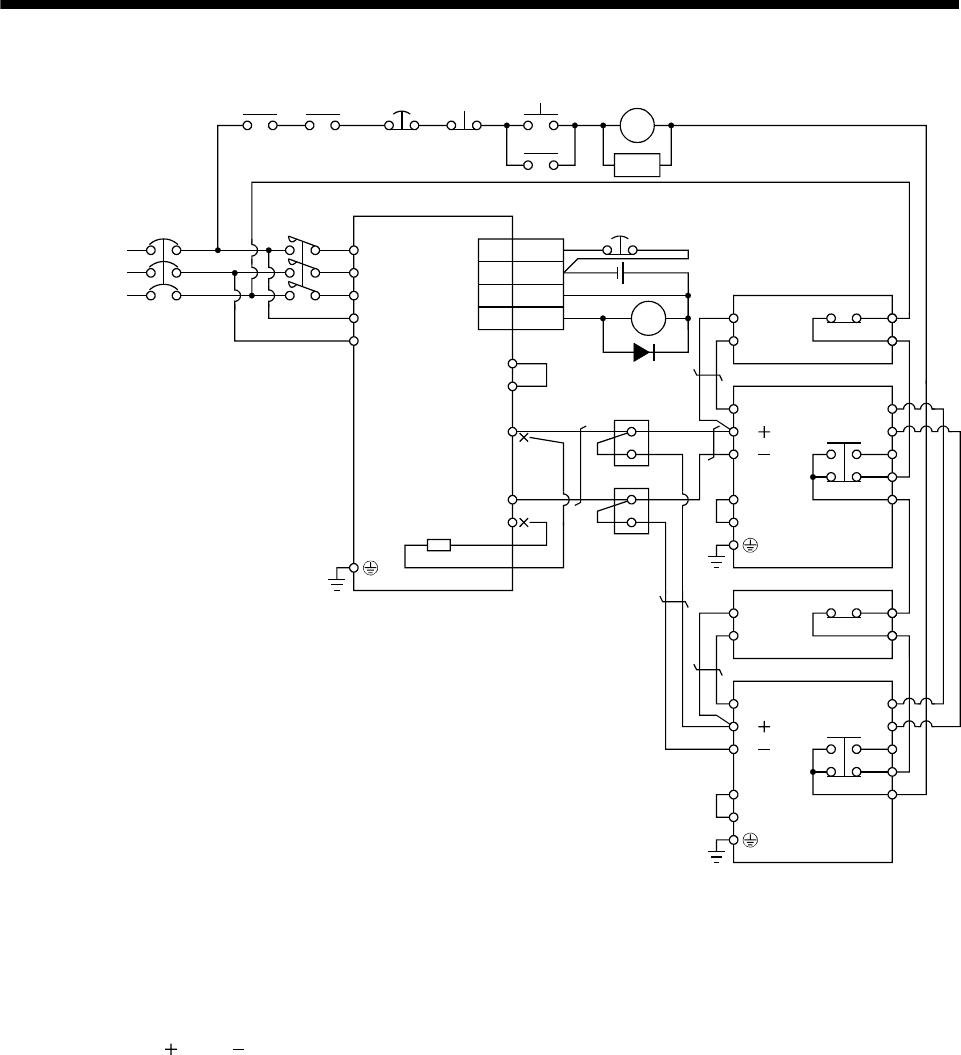

13 - 37

13. OPTIONS AN

D AUXILIARY EQUIPMENT

DOCOM

DICOM

ALM

N/

P/

NFB

24VDC

ALM

RA1

MC

SK

MC

ON

OFFEMG

Servo motor

thermal relay

RA2

(Note 7)

(Note 1)

Power

supply

BUE

SD

PR

B

C

A

SD

MSG

(Note 4)

(Note 6)

17

5

EMG

P

1

P

2

P

N

C

FR-BU2-(H)

FR-BR

Servo amplifier

P

PR

TH2

TH1(Note 5)

MC

Terminal

block

(Note 3)

(Note 11)

(Note 2)

(Note 8)

1

15

CN6

L

1

L

2

L

3

L

11

L

21

(Note 10)

(Note 9)

N/

P/

BUE

SD

PR

B

C

A

SD

MSG

(Note 4)

(Note 6)

FR-BU2-(H)

TH2

TH1(Note 5)

FR-BR

P

PR

(Note 10)

(Note 9)

RA1

Note 1. For power supply specifications, refer to section 1.2.

2. For the servo amplifier of 5k and 7kW, always disconnect the lead of built-in regenerative resistor, which is connected to the P

and C terminals. For the servo amplifier of 11k and 15kW, do not connect a supplied regenerative resistor to the P and C

terminals.

3. Always connect P

1 and P2 terminals (P1 and P for the servo amplifier of 11k and 15kW) (Factory-wired). When using the power

factor improving DC reactor, refer to section 13.11.

4. Connect the P/

and N/ terminals of the brake unit to a correct destination. Wrong connection results in servo amplifier and

brake unit malfunction.

5. Contact rating: 1b contact, 110VAC_5A/220VAC_3A

Normal condition: TH1-TH2 is conducting. Abnormal condition: TH1-TH2 is not conducting.

6. Contact rating: 230VAC_0.3A/30VDC_0.3A

Normal condition: B-C is conducting/A-C is not conducting. Abnormal condition: B-C is not conducting/A-C is conducting.

7. For the servo amplifier of 11kW or more, connect the thermal relay censor of the servo amplifier.

8. Do not connect more than one cable to each P and N terminals of the servo amplifier.

9. Always connect BUE and SD terminals (Factory-wired).

10. Connect the MSG and SD terminals of the brake unit to a correct destination. Wrong connection results in servo amplifier and

brake unit malfunction.

11. For the cable to connect the terminal block and the P and N terminals of the servo amplifier, use the cable indicated in (4) (b)

in this section.