3 - 2

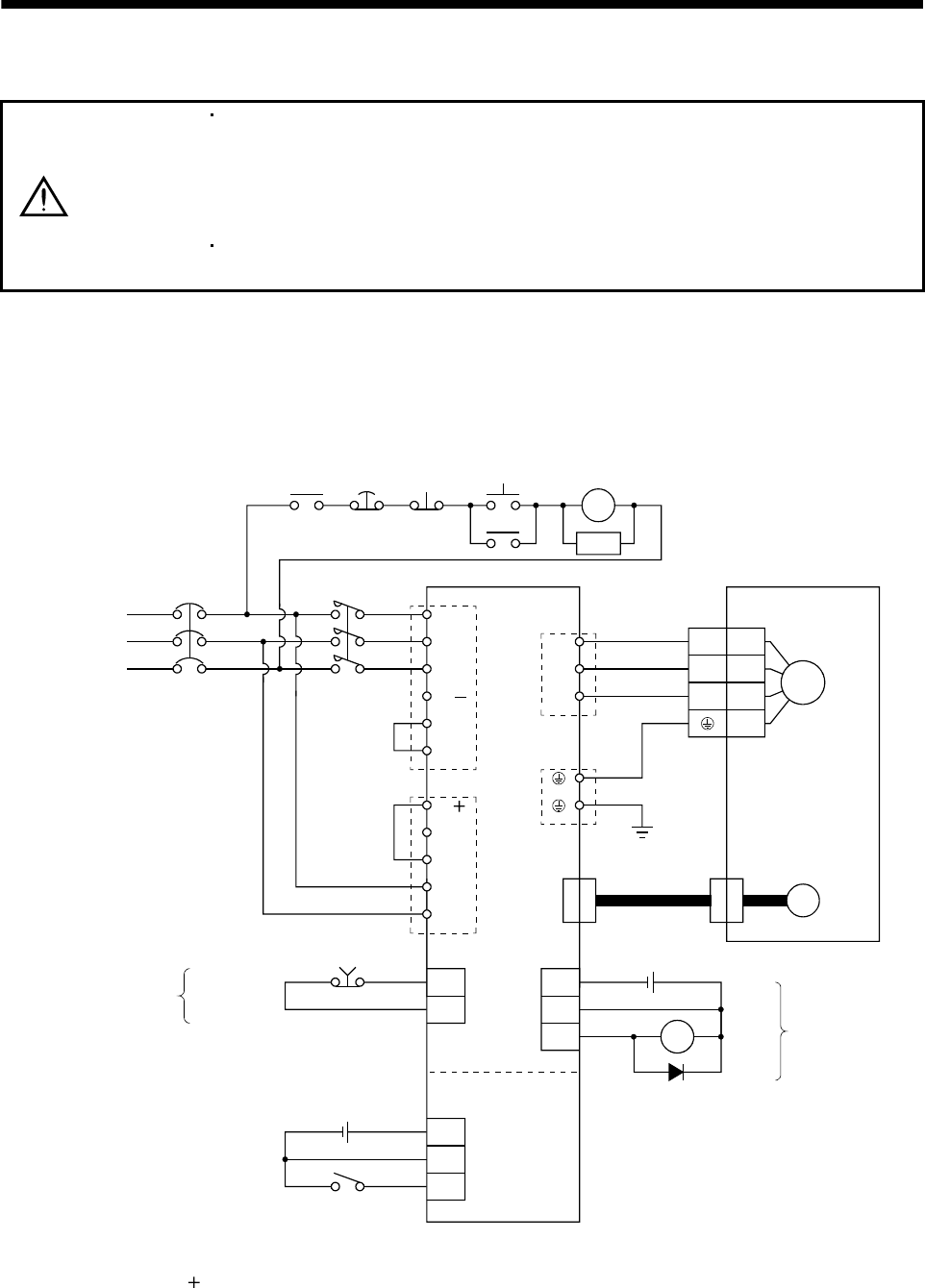

3. SIGNALS AND WIRING

3.1 Input power supply circuit

CAUTION

Always connect a magnetic contactor (MC) between the main circuit power supply

and L

1, L2, and L3 of the servo amplifier, and configure the wiring to be able to shut

down the power supply on the side of the servo amplifier’s power supply. If a

magnetic contactor (MC) is not connected, continuous flow of a large current may

cause a fire when the servo amplifier malfunctions.

Use the trouble (ALM) to switch power off. Otherwise, a regenerative transistor

fault or the like may overheat the regenerative resistor, causing a fire.

Wire the power supply and main circuit as shown below so that the servo-on (SON) turns off as soon as alarm

occurrence is detected and power is shut off.

A no-fuse breaker (NFB) must be used with the input cables of the power supply.

(1) For 3-phase 200 to 230VAC power supply to MR-J3-10T to MR-J3-350T

P( )

RA

NFB MC

L

1

L

2

L3

P1

P

2

SK

MC

ON

OFF

MC

L11

L

21

N( )

D

C

U

V

W

CNP1

CNP3

PE

CNP2

U

V

W

2

3

4

1

M

CN2

EMG

ALM

RA

DICOM

DOCOM

DOCOM

CN6 CN6

SON

DICOMD

CN10

MR-J3-D01

DOCOMD

Servo-on

Forced

stop

Servo amplifier

Servo motor

Motor

3-phase

200 to

230VAC

(Note 1)

(Note 2)

(Note 3)

Encoder cable

Encoder

24VDC

Trouble

(Note 4)

24VDC

(Note 4)

(Note 5)

Forced stop

Note 1. Always connect P1 and P2. (Factory-wired.) When using the power factor improving DC reactor, refer to section 13.11.

2. Always connect P (

) and D. (Factory-wired.) When using the regenerative option, refer to section 13.2.

3. For encoder cable, use of the option cable is recommended. Refer to section 13.1 for selection of the cable.

4. For the sink I/O interface.

For the source I/O interface, refer to section 3.8.3.

5. Refer to section 3.10.