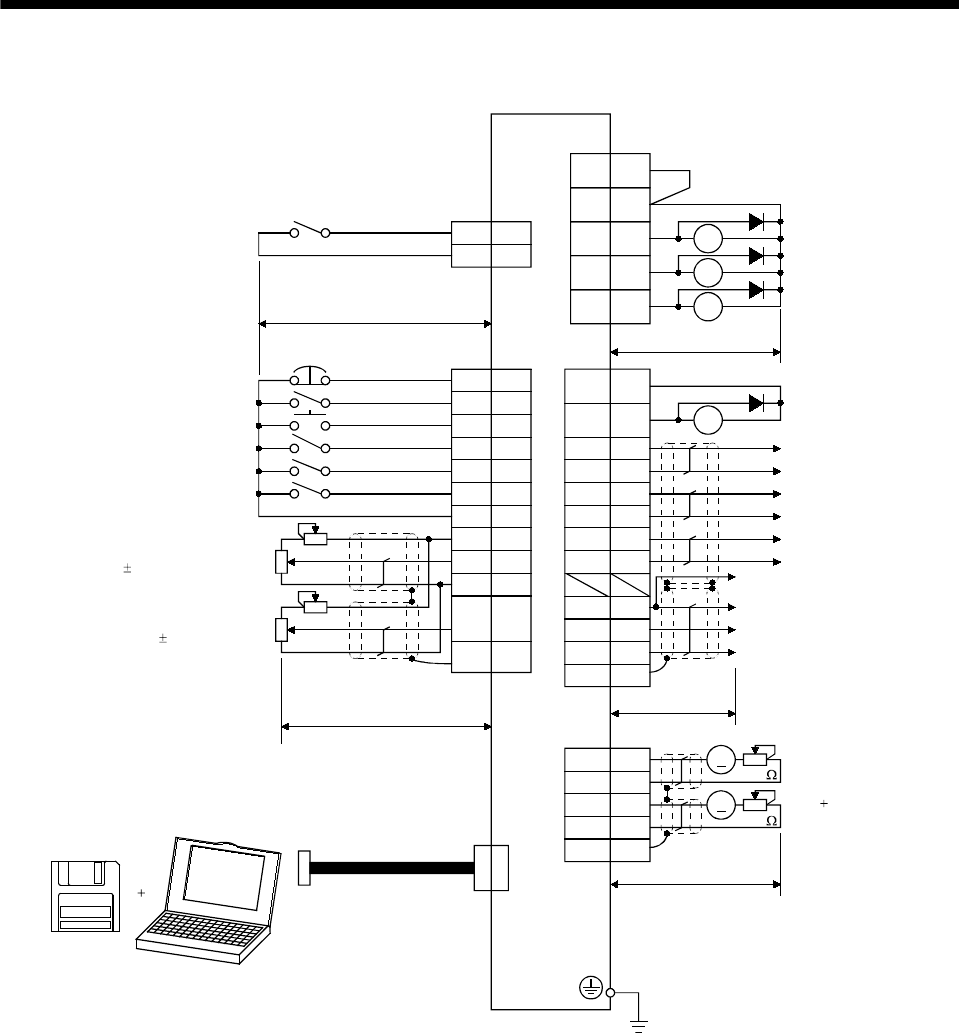

3 - 8

3. SIGNALS AND WIRING

3.1.3 Torque control mode

RA1

RA2

RA3

18

10

SP1

SG

15

5

14

9

8

10

1

11

EMG

SON

RES

RS1

RS2

SG

SD

P15R

LG

12

ALM

19 ZSP

6VLC

15

5

14

7

16

17

4

LZ

LZR

LA

LAR

LB

LBR

LG

OP

P15R

SD

1

6

CN1B

CN3

13

8

7SP2

TC

2VLA

19 RD

RA4

CN1A

3 VDD

COM

9COM

4

13

3

SD

LG

14

MO1

LG

MO2

CN3

A

A

Speed selection 1

Servo amplifier

CN1A

(Note 4,8)

CN1B

(Note 4)

10m(32ft) max.

(Note 4,8) (Note 4,8)

Plate

(Note 3) Emergency stop

Servo-on

Reset

Forward rotation start

Reverse rotation start

Speed selection 2

Upper limit setting

Analog speed limit

0 to 10V/rated speed

Upper limit setting

Analog torque command

8V/max. torque

(Note 9)

MR Configurator

(Servo configuration

software)

Personal

computer

(Note 7)

Communication cable

2m(6.5ft) max.

Plate

Plate

(Note 7)

Analog monitor

Max. 1mA

Reading in both

directions

10k

10k

2m(6.5ft) max.

(Note 4,8,12)

(Note 1)

Control common

Encoder Z-phase pulse

(open collector)

Encoder Z-phase pulse

(differential line driver)

Encoder A-phase pulse

(differential line driver)

Encoder B-phase pulse

(differential line driver)

(Note 10)

Trouble

Zero speed

Limiting torque

(Note 2,5)

Ready

(Note 6)

(Note 4,8)

(Note 11)

2m(6.5ft) or less

10m(32ft) or less

Control common