5 - 9

5. PARAMETERS

Class No. Symbol Name and function

Initial

value

Unit

Setting

range

28 TL1

Internal torque limit 1

Set this parameter to limit servo motor torque on the assumption that the

maximum torque is 100[%].

When 0 is set, torque is not produced.

When torque is output in analog monitor, this set value is the maximum

output voltage (

4V). (Refer to Section 3.3.5 (2))

100 % 0

to

100

29 0

30 0

31 0

32

For manufacturer setting

Do not change this value any means.

0

33 MBR Electromagnetic brake sequence output

Used to set the delay time (Tb) between electronic brake interlock (MBR

)

and the base drive circuit is shut-off.

100 ms 0

to

1000

34 GD2 Ratio of load inertia moment to servo motor inertia moment

Used to set the ratio of the load inertia moment to the servo motor shaft

inertia moment. When auto tuning mode 1 and interpolation mode is

selected, the result of auto tuning is automatically used.

(Refer to section 6.2.1)

In this case, it varies between 0 and 1000.

70 0.1

times

0

to

3000

35 PG2 Position loop gain 2

Used to set the gain of the position loop.

Set this parameter to increase the position response to level load

disturbance. Higher setting increases the response level but is liable to

generate vibration and/or noise.

When auto tuning mode 1

2 and interpolation mode is selected, the result

of auto tuning is automatically used.

35 rad/s 1

to

1000

36 VG1 Speed loop gain 1

Normally this parameter setting need not be changed.

Higher setting increases the response level but is liable to generate

vibration and/or noise.

When auto tuning mode 1

2, manual mode and interpolation mode is

selected, the result of auto tuning is automatically used.

177 rad/s 20

to

8000

37 VG2 Speed loop gain 2

Set this parameter when vibration occurs on machines of low rigidity or

large backlash. Higher setting increases the response level but is liable to

generate vibration and/or noise.

When auto tuning mode 1

2 and interpolation mode is selected, the result

of auto tuning is automatically used.

817 rad/s 20

to

20000

38 VIC Speed integral compensation

Used to set the integral time constant of the speed loop.

Lower setting increases the response level but is liable to generate vibration

and/or noise.

When auto tuning mode 1

2 and interpolation mode is selected, the result

of auto tuning is automatically used.

48 ms 1

to

1000

39 VDC Speed differential compensation

Used to set the differential compensation.

Made valid when the proportion control (PC

) is switched on.

980 0

to

1000

40 0

41

For manufacturer setting

Do not change this value any means.

0000

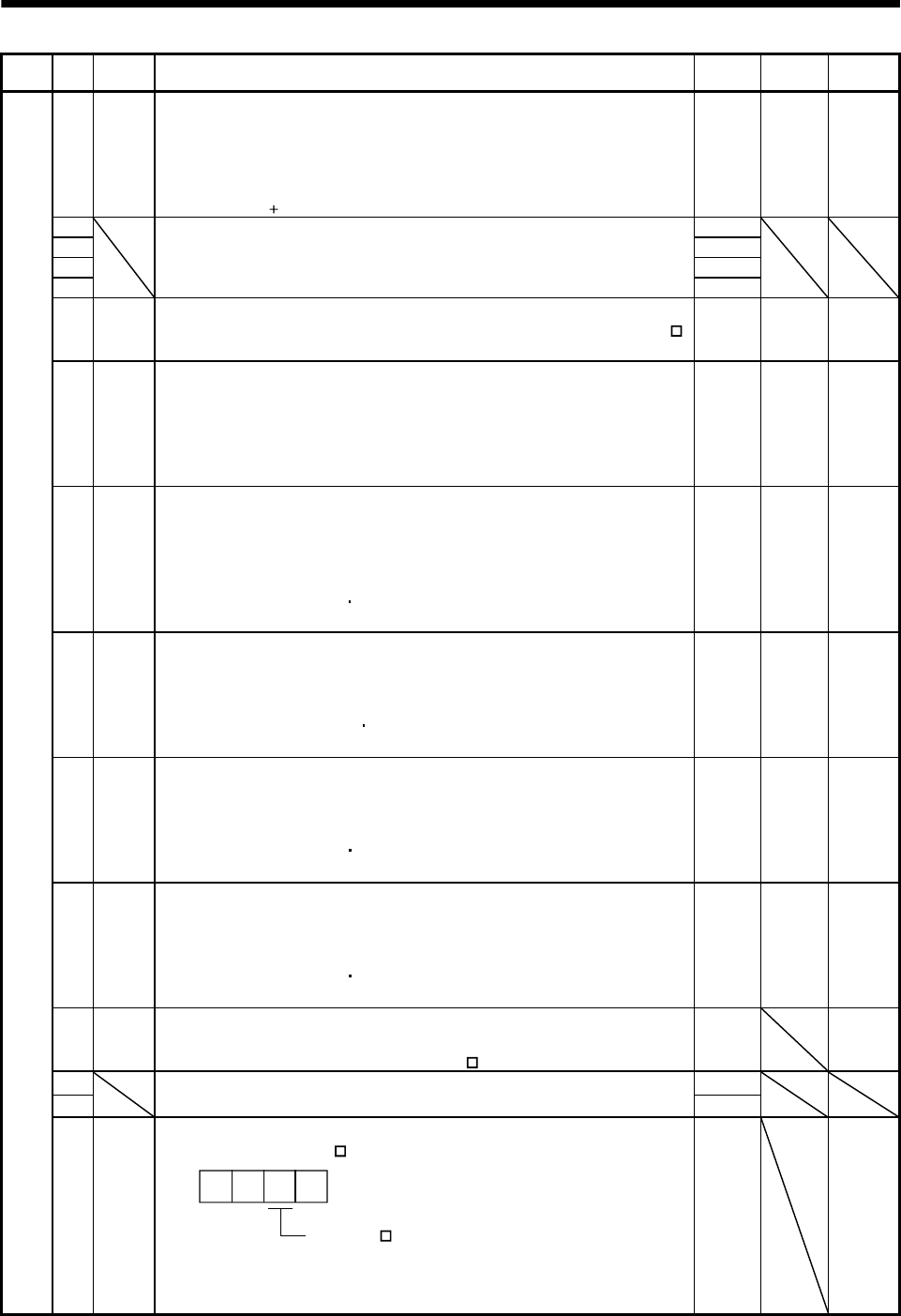

Expansion DRU parameters 1

42 *DI1 Input signal selection 1

Used to set the clear (CR

).

0 0

Clear (CR ) selection

0: Droop pulses are cleared on the leading edge.

1: While on, droop pulses are always cleared.

3

0003

Refer to

Name

and

function

column.