4 - 22

4. OPERATION

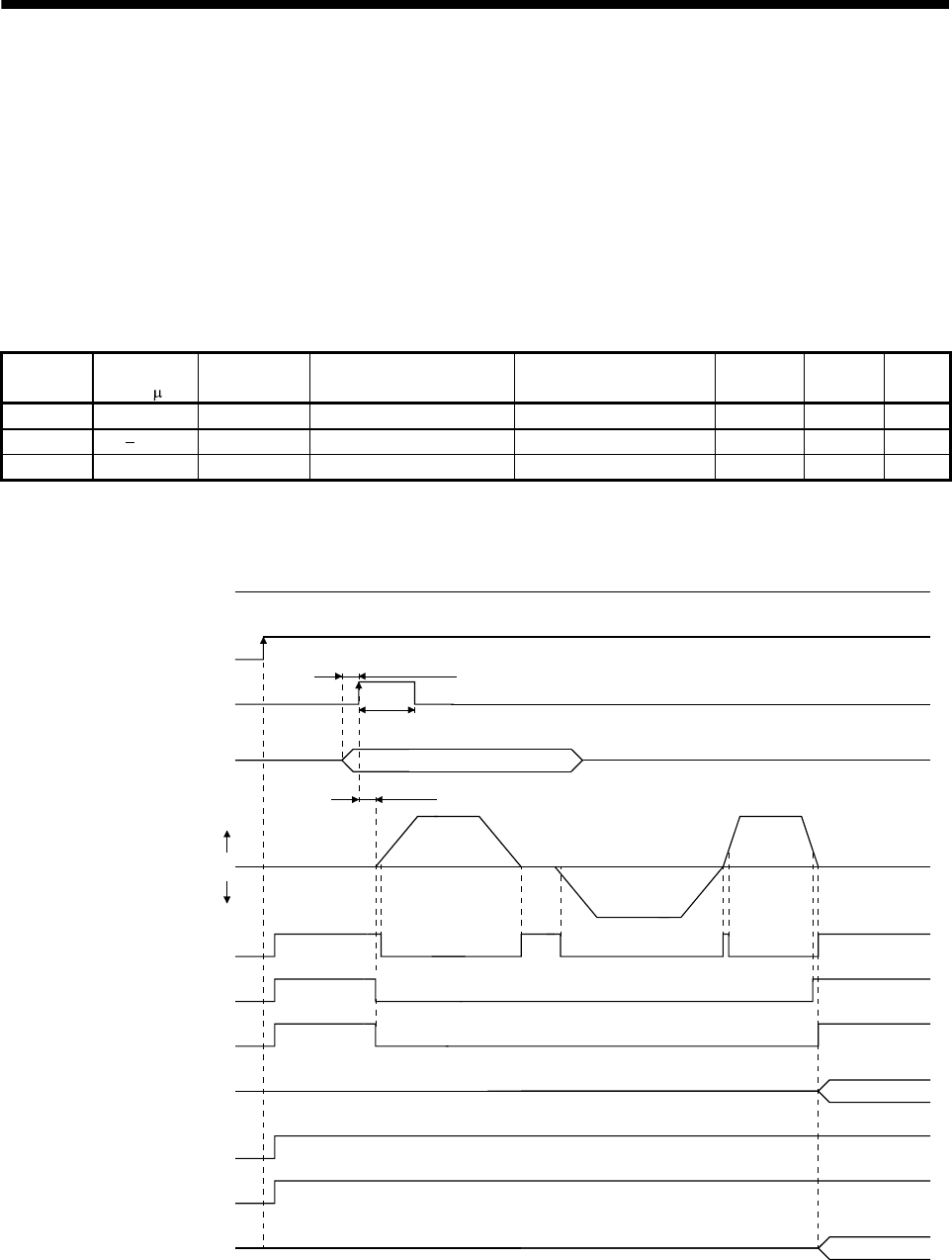

(c) Automatic continuous positioning operation

By setting "1" or "3" to the auxiliary function of the point table, the continuous positioning to the next

point table No. can be executed.

By setting "1" or "3" to the auxiliary function up to the point table No. 254, a continuous automatic

positioning is available at a maximum of 255 speeds. Set "0" to the auxiliary function of the last point

table.

As an example, the operation in the absolute value command system is shown using the setting values

in the following table.

Here, the point table No.1 uses the absolute value command system, the point table No.2 the

incremental value command system, and the point table No.3 the absolute value command system.

Point table

No.

Position data

[10

STM

m]

Servo motor

speed [r/min]

Acceleration time constant

[ms]

Deceleration time constant

[ms]

Dwell [ms]

Auxiliary

function

M code

1 5.00 3000 100 150 100 1 05

2 6.00 2000 100 100 0 3 15

3 3.00 3000 50 50 0 0 (Note) 25

Note. Always set "0" or "2" to the auxiliary function of the last point table among the consecutive point tables.

0: When point table is used in absolute value command system

2: When point table is used in incremental value command system

Point table

No. 1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

5ms or more

Ready (RD)

Trouble (ALM)

Point table No.

Servo motor speed

Forward

rotation

0r/min

ON

OFF

Forward rotation

start (ST1)

1

ON

OFF

3ms or less

1

05

Point table

No. 2

Point table

No. 3

Servo-on (SON)

Automatic/manual

selection (MD0)

Rough match (CPO)

Movement finish

(MEND)

Point table No. out put

(PT0 to PT7)

M code output

Reverse

rotation

In position (INP)

3ms or more (Note)

Note. External input signal detection delays by the input filter setting time of parameter No. PD19. Also, make up a sequence that will

change the point table selection earlier by the time that takes into account the output signal sequence from the controller and the

variation of a signal change due to the hardware.