13 - 56

13. OPTIONS AN

D AUXILIARY EQUIPMENT

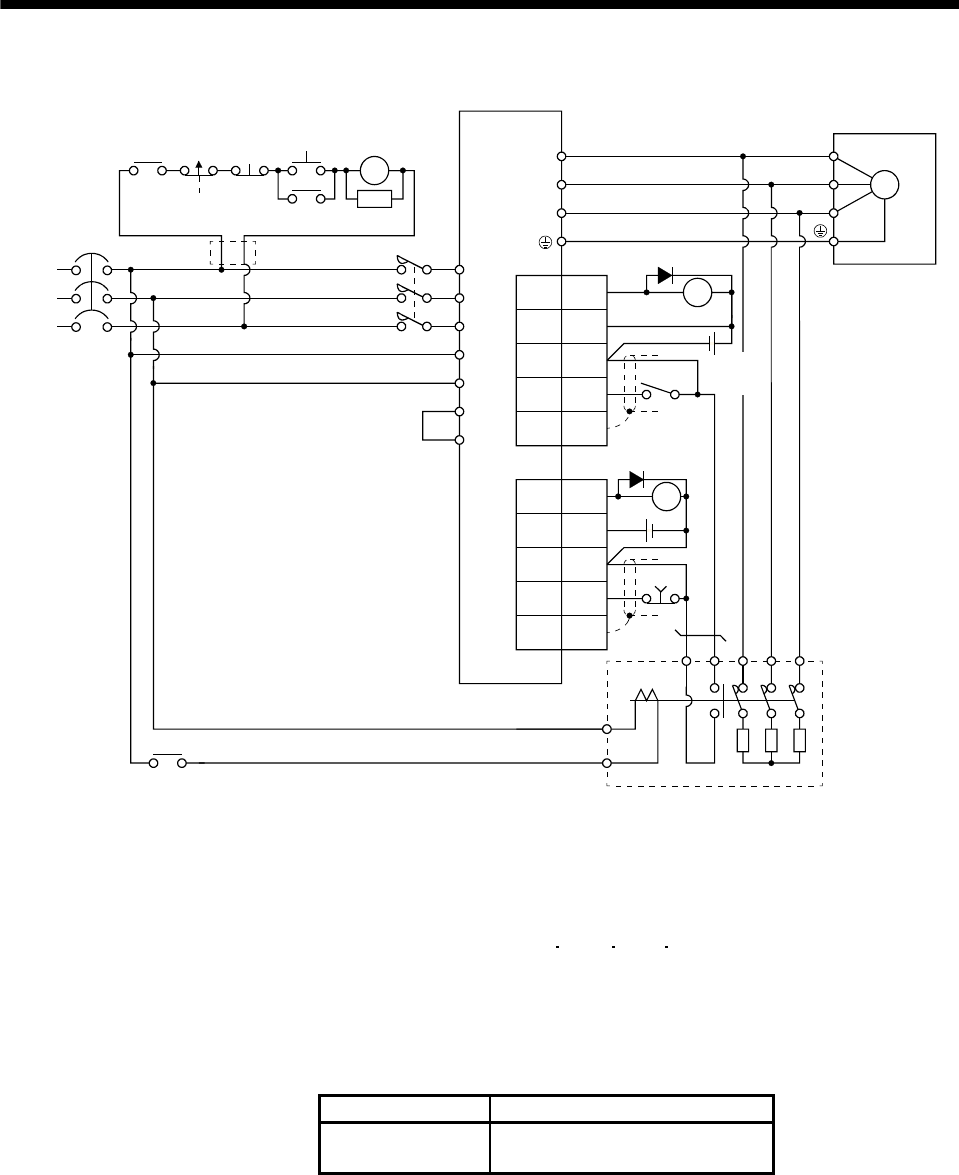

(2) Connection example

Plate SD

NFB

MC

L

11

L21

U

V

W

U

V

W

M

13 U14 V W

External dynamic brake

a

b

Servo amplifier

Servo motor

RA2

MC

SK

MC

ON

OFF

ALM

RA1

Operation-ready

EMG

(Note 1)

L3

L

2

L1

(Note 6)

Power

supply

P

P

1

(Note 2)

(Note 3)

17

21

DB

DOCOMD

SON

RA2

24VDC

(Note 4)

CN10

14

DICOMD

5

17

1

Plate

DICOM

DOCOM

EMG

SD

24VDC

(Note 4)

CN6

15 ALM

RA1

(Note 5)

(Note 7)

Note 1. Terminals 13, 14 are normally open contact outputs. If the dynamic brake is seized, terminals 13, 14 will open.

Therefore, configure up an external sequence to prevent servo-on.

2. When using the servo amplifier of 11k to 22kW, make sure to connect P

1

and P. (Factory-wired.)

When using the power factor DC reactor, refer to section 13.11.

3. Assign the dynamic brake sequence (DB) in the parameters No.PD09

PD10 Po08 Po09.

4. 24VDC can be supplied from the same power supply.

5. Stepdown transformer is required for coil voltage of magnetic contactor more than 200V class in 400V class servo amplifiers.

6. Refer to section 1.2 for the power supply specification.

7. The power supply voltage of the inside magnet contactor for 400V class dynamic brake DBU-11K-4 and DBU-22K-4 is

restricted as follows. When using these dynamic brakes, use them within the range of the power supply.

Dynamic brake Power supply voltage

DBU-11K-4

DBU-22K-4

1-phase 380 to 463VAC 50Hz/60Hz